About Anuprerna Studio

Our Production Process, From Initial Design To Final Product, Is The Embodiment Of Our Commitment To Building A Transparent Supply Chain In What We Do. The Art Of Hand Weaving, In Bengal, Is An Ancient Craft From Times When Fabrics Were Being Exported To Roman And Chinese Empires. The Hot And Humid Indigenous Climate Inspired Artisans For Fabric Manufacturing To Produce The Most Delicate And Translucent Fabrics and Products.

CRAFTING ELEGANCE

Textile Studio Amidst Weaving Clusters

At the heart of weaver clusters, surrounded by weaving communities specialized in multiple crafts & traditions, our small production studio provides a convenient common place for our artisans. From the time of inception of design ideas to final execution takes place here. Due to the convenient location close to certain artisan clusters, we can quickly plan & meet with artisans as and when needed.

The Foundation & Beating Heart of Anuprerna

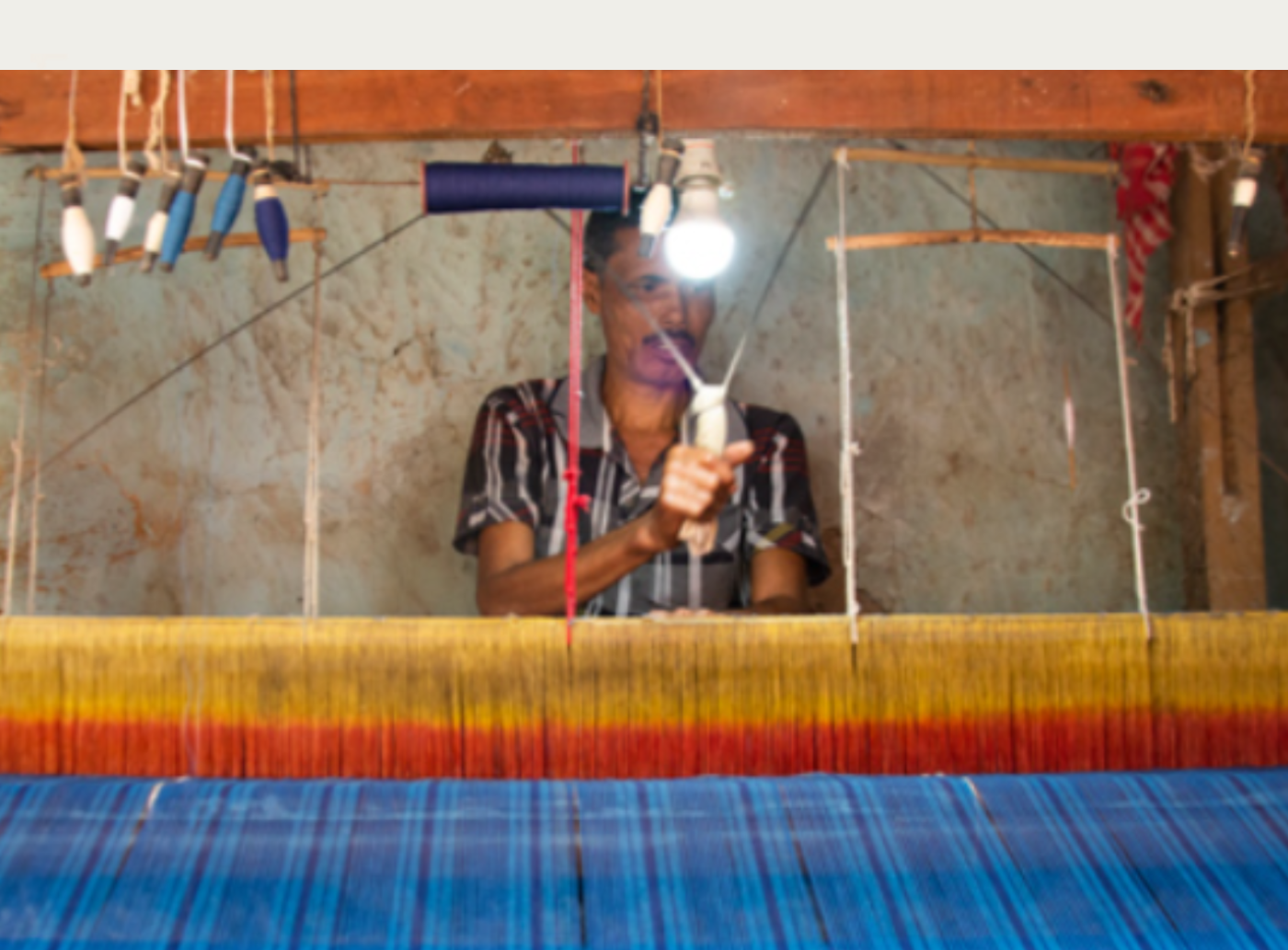

300+ Weavers spread across multiple clusters across the state of Bengal specialized in indigenous weaves & techniques of East India. Primarily each weaver family is involved in the process where both men & women are responsible for hand-woven fabrics and the pre weaving processes.

India, being a country of family & festive, the artisans enjoy working at the comfort of their home, enjoying each festival with their respective communities.It is impossible to walk the length of village roads and not hear the flying shuttles of handlooms as you pass each and every house. We encourage you to visit and experience the traditions, the artisans, and their lifestyle.

From initial Design To The Final Product

We undertake a number of steps in the production process to bring you the best quality of handmade artisanal textiles. The process below describes the journey of the textile/product going through multiple hands, from the inception of the design, patterns to our skilled weavers, inspectors, and seamstresses.

Swatch Reference & Product Design

For new fabric sampling, our designers will come up with new hues, color, and weave construction to develop a range of collections. We also analyze the design provided by our clients to understand the construction and color. We then source a suitable yarn, which matches the requirements of the desired product; the fabric must be durable, aesthetically pleasing, follows exact color & construction, and have a great tactile finish quality. Depending on the crafts we work on the process differs accordingly.

Yarn Processing & Dyeing

Once the suitable yarn is decided, it is processed to be dyed in the desired colours as per the chosen design in our in-house dye unit. We rely on solar energy & hand dyeing process making sure the yarns are dyed uniformly.

We have been strictly using Azo-free reactive GOTS certified dye brands to get better fastness and low-impact dyes on either yarn, fabrics, or other textile products. Once dyed, the yarn is thoroughly inspected to ensure durability, colour fastness, and several other factors.

Craft-Specific Process in Clusters

The desired yarn for both warp & weft once ready, is dispatched to our weavers as per their expertise based on the crafts & techniques the textile to be weaved. Based on different fabric crafts, a different process is followed which is further described in our craft section.

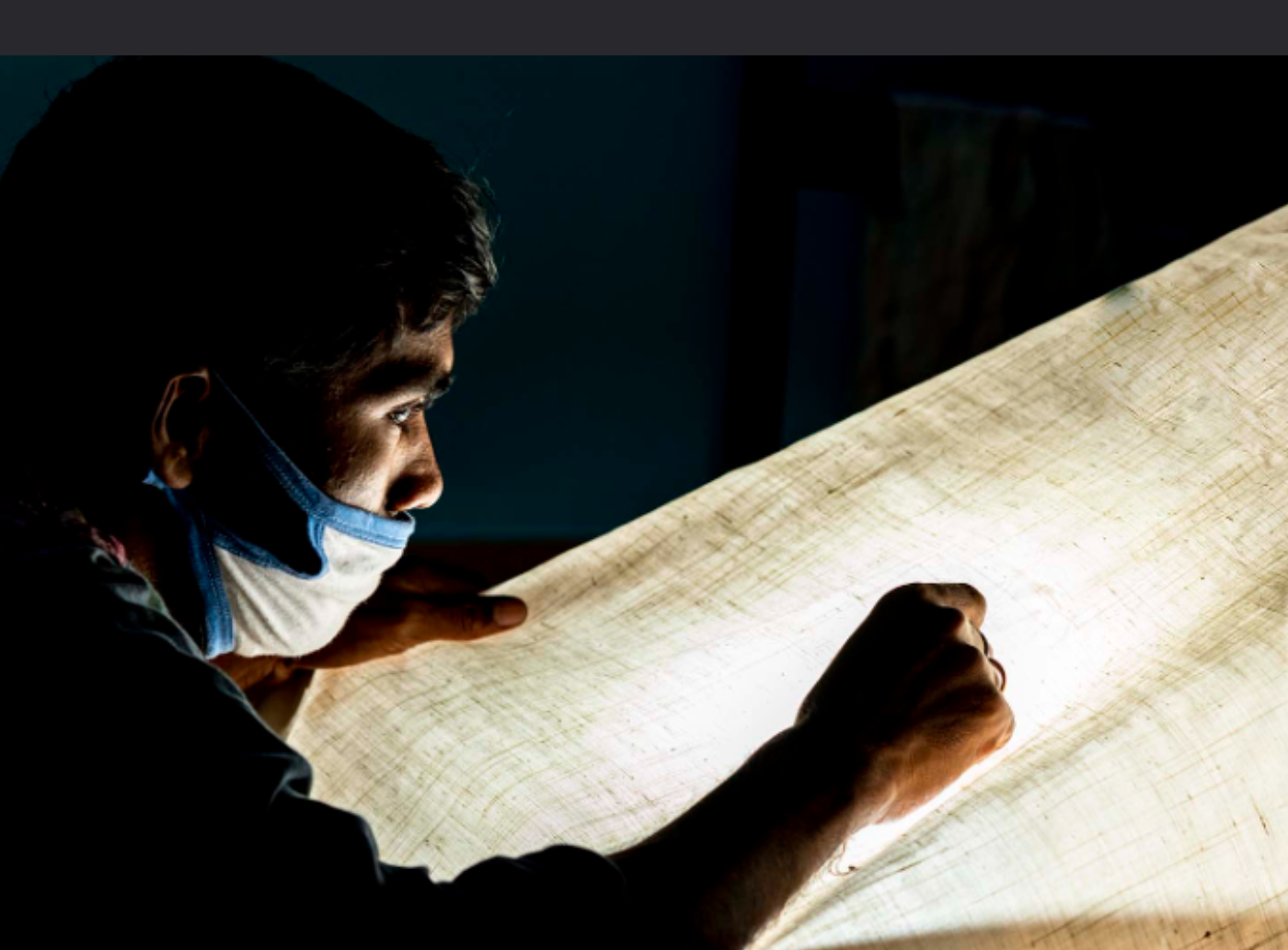

Inspection & Finishing of Fabrics

The textiles once woven are dispatched to our textile studio by our weavers for final processing & inspection. The inspection consists of the fabric being rolled over a lightbox to highlight any faults that may have occurred during weaving. The faults can be sometimes mended with needle and thread and sometimes can be instructed to be modified post-analysis of the first prototype. Once passed, it is further washed & processed to improve the tactile quality before dispatch.

Tailoring

At Anuprerna Production Studio, our tailoring section transforms carefully finished textiles into exquisite products. Our skilled tailors bring to life a wide range of customizable options, including apparels, accessories, and homeware, catering to the unique preferences of our customers. With meticulous attention to detail and specifications, our production unit ensures that each item is crafted with precision, reflecting our commitment to quality and customer satisfaction.

related questions

What steps does Anuprerna take to ensure the quality of handmade artisanal textiles?

arrow_drop_downAnuprerna undertakes a number of steps in the production process, involving multiple hands, from design inception to final inspection.

Does Anuprerna work with specific weaver communities?

arrow_drop_downYes, we work with various weaver communities, empowering them and preserving their craft.

How does Anuprerna ensure that the seamstresses are using ethical practices?

arrow_drop_downAnuprerna ensures fair pay, safe workspaces, and provides training for seamstresses. Ethical standards and sustainable practices are fundamental to our work.

More Blogs

empowering artisans, transforming lives: impact report 2024

2022 anuprerna impact report

about our impact

about the founder

about the brand

about the platform