Construction Of Fabric & Its Significance On Handwoven Fabrics

Each Garment Or Textile Product Has A Fabric Construction That Differs From The Others. This Difference Can Be Seen In The Texture, Weight, Shine, Drape Or Flow Of The Fabrics. That’s Why They Look And Feel Different From Each Other. In Order To Pick The Right Fabric For Any Product, We Need To Understand The Construction Suitable For The Product.

Anuprerna, as a fabric manufacturer committed to quality and innovation, emphasizes the importance of understanding these fabric constructions to ensure the suitability of the product. By comprehending the specific construction requirements for each item, Anuprerna ensures that fabrics are chosen wisely, resulting in products that not only look and feel different but also meet the desired standards of performance and aesthetics.

Introduction

At Anuprerna all our fabrics are handwoven by artisans of Bengal. These artisans specialise in indigenous handweaving techniques. The handwoven fabrics differ from the machine loom produced ones. They are rustic and full of character.

All our fabrics are always made of 100% natural material and as such are gentle on the skin as well as the environment and hypoallergenic.

Besides this, there are some technical parameters of fabric construction that influence its properties discussed below-

1. Fibre characteristics:

The constituent fibre is the most obvious factor. Different kinds of fabric materials will display the characteristics of the fibre it is made of. Fabric made of cotton or linen are highly absorbent, and durable whereas mulberry silk fabric is fine and smooth due to the long filament fibres of silk.

2. Twist per inch i.e. TPI

Yarn with a higher twist is responsible for the fabric being smooth & resistant to pilling.

Beyond a certain level are highly twisted yarn will be lively and tend to twist upon itself to produce snarls. This is crepe fabric. Such fabrics, made from highly twisted yarns, will process a lively handle.

Also, very highly twisted yarn also results in a fabric with a high degree of water repellency. Low twist yarn is used where absorbency is required. Our Khadi fabrics are made of handspun yarns with low TPI which are thus high in absorbency and a great choice for the summers.

3. EPI & PPI:

Picks per inch i.e. PPI and Ends per inch i.e. EPI are a measure of thread density. EPI and PPI affect the compactness of the fabric. The heavier/denser your EPI and PPI, the denser your finished fabric will be. Like shirting fabric or trouser fabric.

For lighter fabric, the epi and PPI should be lower. This is results in loosely woven fabrics which are much flowier like scarves and Saree.

We keep a few loose plain woven fabrics that are ideal for lining and also some of the scarves are comparatively loosely woven which makes them flowy.

Usually, the ends per inch are kept higher than picks per inch. The first reason is the cost of production. Higher PPI causes a direct increase in the weaving cost of the fabric. The second reason is the widthwise shrinkage of the fabric during weaving.

For most of our weaving construction, we maintain a high EPI / PPI ratio to strengthen the fabrics which is only possible by expert handloom weavers

In plain fabrics, the ratio of warp and weft in the plain fabric is kept at 55:45

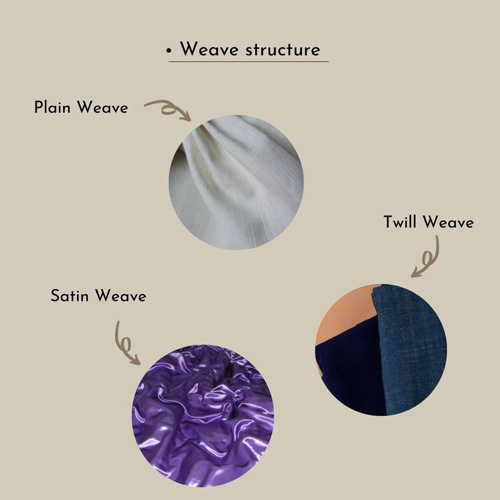

4. Weave structure:

The order of interlacement of warp and weft threads at right angles is known as the woven fabric construction. Woven fabrics are defined as fabrics composed of warp yarns & weft yarns. Warps are the yarns along the length of the fabrics or parallel to the selvedge whereas weft yarns are interlaced with warps in a crosswise direction to make a fabric

Plain Weave

It is the simplest weave and therefore inexpensive to produce. Many fabrics that you commonly wear like mulmul dupattas, organdy and chiffon sarees are all plain weave.

Each and every weft yarn goes alternately under and over the warp yarns across the width of the fabric.

If the yarns are close together, the plain weave fabric has a high thread count and the fabric will be firm and will wear well. Ex-Stripes, Checks, Chambray & Cross colour, Jamdani

Besides, the plain weave is produced in a variety of forms and textures by causing a differential tension, by using various counts of yarn or using warp and weft yarns of different counts in the same fabric.

Fabric construction is the most crucial factor that determines the nature of the textile like - drape, durability, softness, sturdiness, opacity etc. At Anuprerna we give utmost importance to that aspect & provide valuable feedback & training to the artisans to create these beautiful textiles that are at par with international standards.

Other Weaves-

Twill Weave- The twill weave pattern has a clear diagonal line on the face of the fabric. The denim or jean fabric you wear is a twill weave. It is a very strong and durable weave. It is therefore commonly used in men’s suit and coat fabrics. Twill weave fabrics show soil-less more quickly than plain weave.

Satin Weave- The satin weave is characterized by floating yarns used to produce a high lustre on one side of the fabric. Warp yarns of low twist float or pass over four or more filling yarns. A fabric with higher floats is also likely to absorb more water.

Satin has a luxurious look and feel. It is also smooth and soft. For this reason, it is preferred for nightwear, pillowcases, evening gowns, shirts and neckties. scrunchies, etc

Visuals of our fabrics

related question

What are the steps in preparing fabric before construction?

arrow_drop_downFabric preparation before construction typically involves steps such as washing, drying, pressing, and cutting the fabric to the desired size and shape for the intended garment or project.

How fabrics are made from fibers?

arrow_drop_downFabrics are made from fibers through processes like spinning, weaving, or knitting, where fibers are transformed into continuous strands or fabric structures suitable for various textile applications.

What are the different methods of making fabric?

arrow_drop_downThe different methods of making fabric include weaving, knitting, and nonwoven techniques such as felting or bonding.

What are the steps in fabric preparation?

arrow_drop_downFabric preparation typically involves steps such as desizing, scouring, bleaching, dyeing, printing, and finishing to prepare the fabric for further processing or end use.

More Blogs

the scrap fabric solution, from clutter to creation

the art of sustainable recyclability

indian handloom in contemporary world

sustainability through handloom manufacturing

how to identify handloom fabrics in a powerloom world

ketia silk - a peace lover