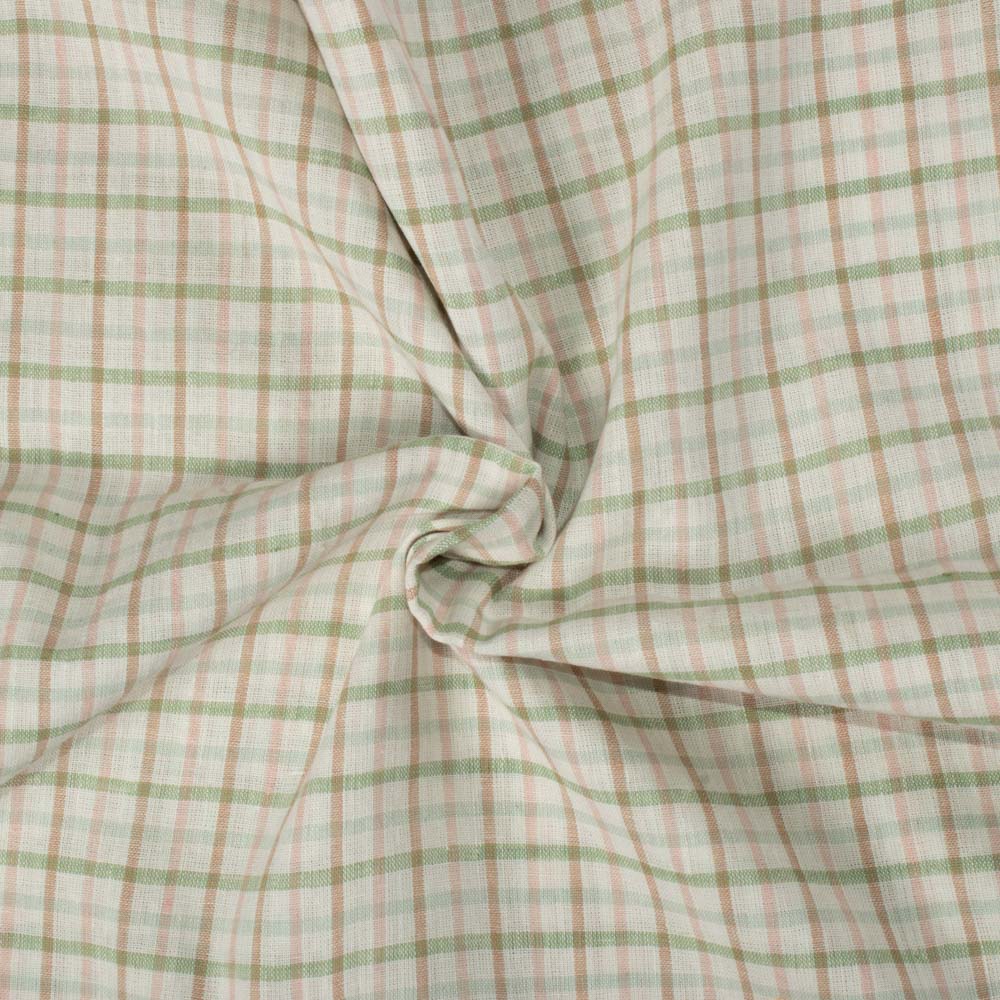

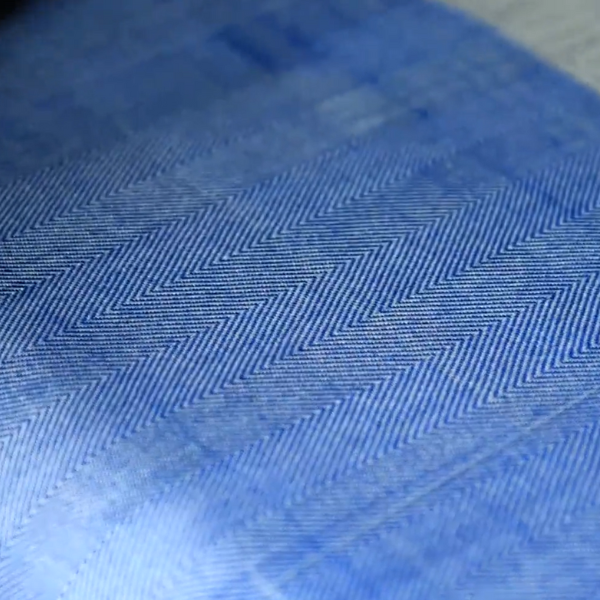

HANDWOVEN LINEN

Linen Is One Of The Oldest Textiles To Have Been Woven. The Linen Fiber Is Actually The Fiber From The Flax Plant And The Fabric Made From It Is Strong & Durable. Though Expensive Than Cotton, Flax Fiber Cloth Has Come To Be Appreciated Again Due To Its Desirable Properties, Especially For The Summer Months. At Anuprerna, The Linen Fabrics Are Always Handwoven, Which Are Stronger Than The Machine Woven Ones. We Have Discussed Here How Linen Is Made Step By Step.

LINEN DYEING & WEAVING PROCESS

INTRODUCTION

Linen is a sustainable fabric made from bast fiber of Flax plant. This textile appears to be one of the oldest in the world and its history goes back several thousands of years. Linen is very strong and absorbent and dries faster than cotton.

It is relatively easy to take care of, since it resists dirt and stains, has no lint or pilling tendency, and can be dry-cleaned, machine-washed, or steamed. It can withstand high temperatures and has only moderate initial shrinkage. It also softens as you wear it over time. Being a durable and one of the most comfortable fabric material, makes it a great choice for making apparels.

HISTORY OF FLAX CLOTH

The making of linen cloth had started several thousand years ago in different parts of the world. Dyed flax fiber have been discovered in a cave in Southeastern Europe dated 36,000 years ago which suggests ancient civilizations have been creating linen from flax fibres since a very early time.

In ancient Mesopotamia, flax was domesticated and linen was produced though used mainly by the wealthier class of the society. While in ancient Egypt, linen was used for mummification and burial shrouds. It was also worn as clothing daily.

PROCESS OF MANUFACTURING LINEN- STEP 1: CULTIVATING, HARVESTING & STOOKING

STEP 1: CULTIVATING, HARVESTING & STOOKING

Cultivating-The process of growing flax, from sowing the seeds to reaping the fully developed plant, typically takes around 100 days.

Harvesting involves uprooting the plant instead of using a cutting method once the flax starts to turn brown.

Stooking refers to the practice of gathering plants and securing them into bunches known as beets. These beets are left upright to undergo a thorough drying process.

STEP 2: RIPPLING

The method employed to extract flax seeds and eliminate leaves and other unwanted materials involves running the plant through coarse combs.

STEP 3: RETTING

Retting refers to the natural decomposition or rotting of the tough outer bark that surrounds the flax fiber. Retting can be dew or water retting.

STEP 4: BREAKING & SCUTCHING

The fibrous strands that have been loosened are directed through rollers that divide the stem into smaller fragments known as shive, which are essentially pieces of bark.

Subsequently, these shives are passed through a scutching machine, which effectively separates and extracts the flax fiber from the stalk through the scutching process.

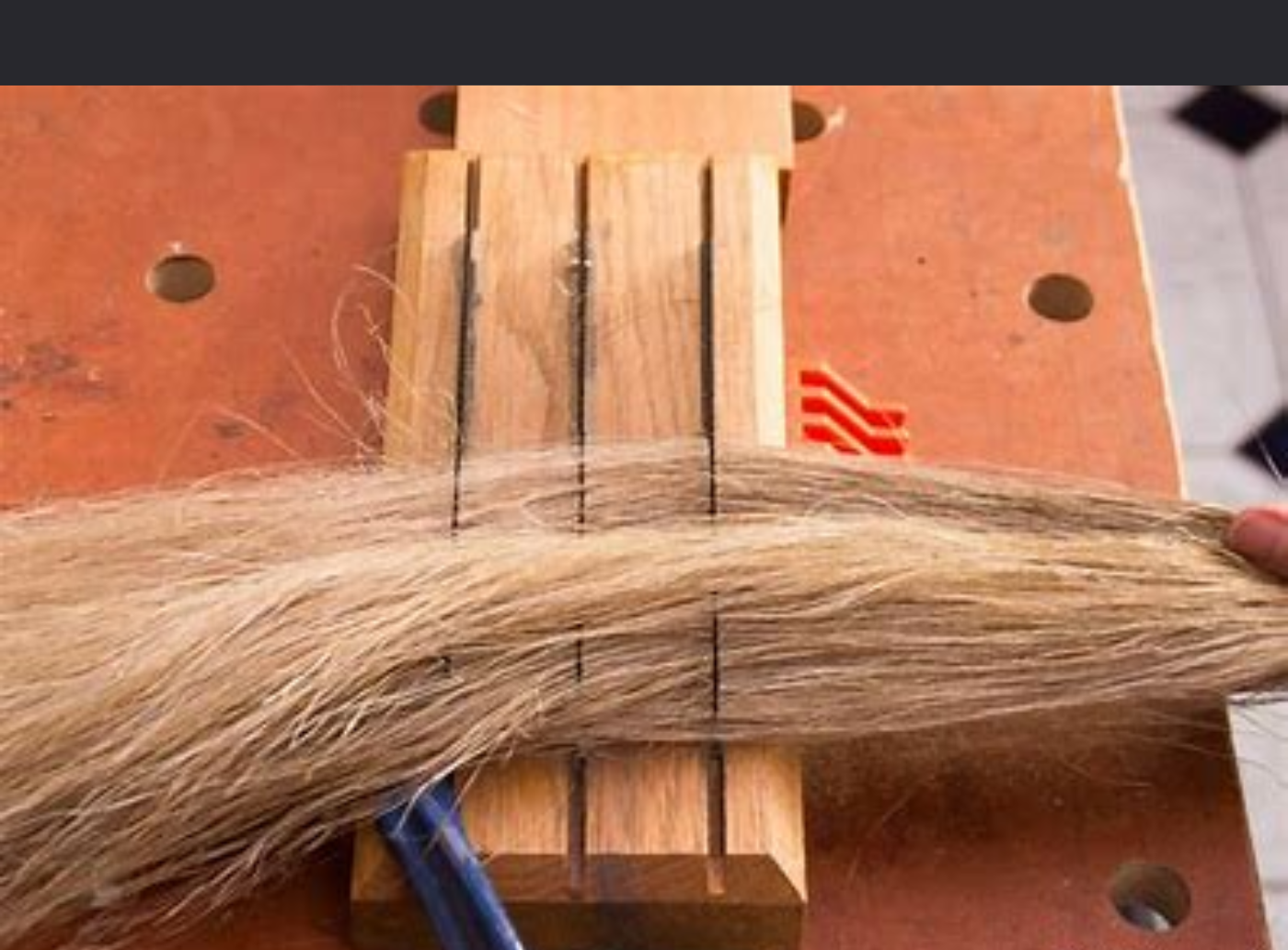

STEP 5: HACKLING

In the process of hackling, the fibers undergo combing and straightening to prepare them for spinning. This step serves to separate the shorter fibers from the longer and more premium linen fibers.

STEP 6: SPINNING

In the process of spinning linen, elongated fibers of equal length are merged together by aligning them in a parallel manner, causing the ends to interweave and resulting in a continuous strand known as sliver.

This sliver is then passed through a series of rollers to form a thicker strand called roving. Subsequently, the linen rovings are placed onto a spinning frame where they are stretched into thread and eventually wound onto bobbins and spools.

APPLICATIONS OF LINEN

Many products can be made with the linen fiber fabric: aprons, bags, towels, napkins, bed linens, tablecloths, runners, chair covers, and men's and women's wear. Many other products, including home furnishing items, are also often made from linen. Linen is one of the preferred traditional supports for oil painting due to its strength, durability and archival integrity. It has also been a popular choice for bandages for centuries as its naturally anti-bacterial.

At Anuprerna, the manufacturing of linen involves the fabric being handwoven which is actually stronger, crisper, and slightly heavier initially, than the machine-woven ones. Besides this, being handwoven, the linen fabrics are sustainable as well.

ADVANTAGES & DISADVANTAGES OF LINEN

frequently asked questions

Can handwoven linen fabrics be customized with specific colors or patterns?

arrow_drop_downYes, at Anuprerna our skilled artisans can create custom handwoven linen fabrics with specific colors and patterns based on individual preferences and design concepts.

What are the common applications of handwoven linen fabrics?

arrow_drop_downHandwoven linen fabrics find common applications in a wide range of products, including clothing, home textiles, and more. Its timeless appeal and versatility make it a favored choice in both fashion and interior design.

Is Linen a good fabric choice for Summers?

arrow_drop_downLinen is one of the most summer-ready fabrics; It is breathable and absorbent. It also releases moisture into the air and remains dry. Linen fabric can absorb up to 20% of its weight in moisture before you can feel any dampness. This is because of its structure which soaks up water to its center. Thus, it is a good fabric for summer weather – in moderate heat, your sweat will be absorbed, keeping you cool and comfortable.

How do I care for Handwoven Linen fabric?

arrow_drop_downTo take care of your linens, avoid washing them in hot water instead, wash them with lukewarm or even cold water. Avoid harsh rubbing or wringing, and gently squeeze out excess water. Hang it to dry in a shaded area to prevent fading. Iron the linen when it is still damp. This process will help your linen to become softer.

Is linen fabric prone to wrinkles, and how can one minimize wrinkling?

arrow_drop_downLinen is known for its tendency to wrinkle, which is part of its natural charm. To minimize wrinkles, remove linen garments promptly from the dryer when they are slightly damp, or iron them with a steam setting. Embracing the relaxed, lived-in look of linen is also an option.

More Stories

piece dyed fabrics

yarn dyed khadi cotton

handwoven merino wool

patachittra wall art

eri peace silk

naturally dyed block printing