SCREEN PRINTING

The Screen Printing Process Is A Direct Printing Technique Where A Mesh Is Used To Transfer Ink Onto A Substrate, Except In Areas Made Impermeable To The Ink By A Blocking Stencil. Traditionally, The Process Was Also Called Silk Screen Print Because Silk Was Used In The Process. It Is Also Known As Serigraphy And Serigraph Printing. We Discuss About The Craft Along With The Pros And Cons Of Screen Printing.

WHAT IS SCREEN PRINTING?

Screen printing is a technique where a mesh or screen transfers ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. The impermeable areas are created with the help of photographic emulsion. The photographic emulsion technique involves the photosensitive substance reacting with light and becoming insoluble. This screen is made of fine material.

Various types of mesh sizes will determine the outcome and look of the finished design on the material. The fabric count is such that it is possible for the print paste to pass through the interstices between the yarns.

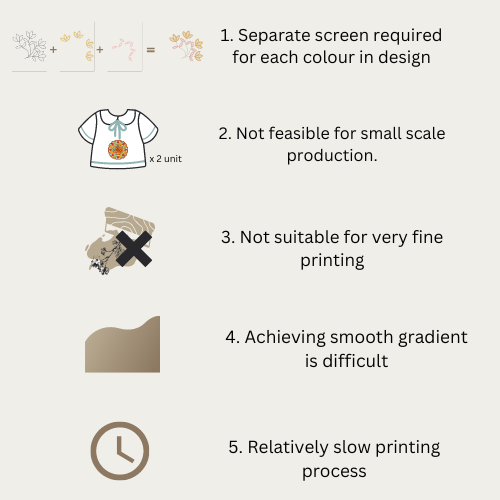

As with other methods of color transfer, the number of screens needed for a design will depend on the number of colors used. The width of the screen decides the repeat size of the print.

HISTORY

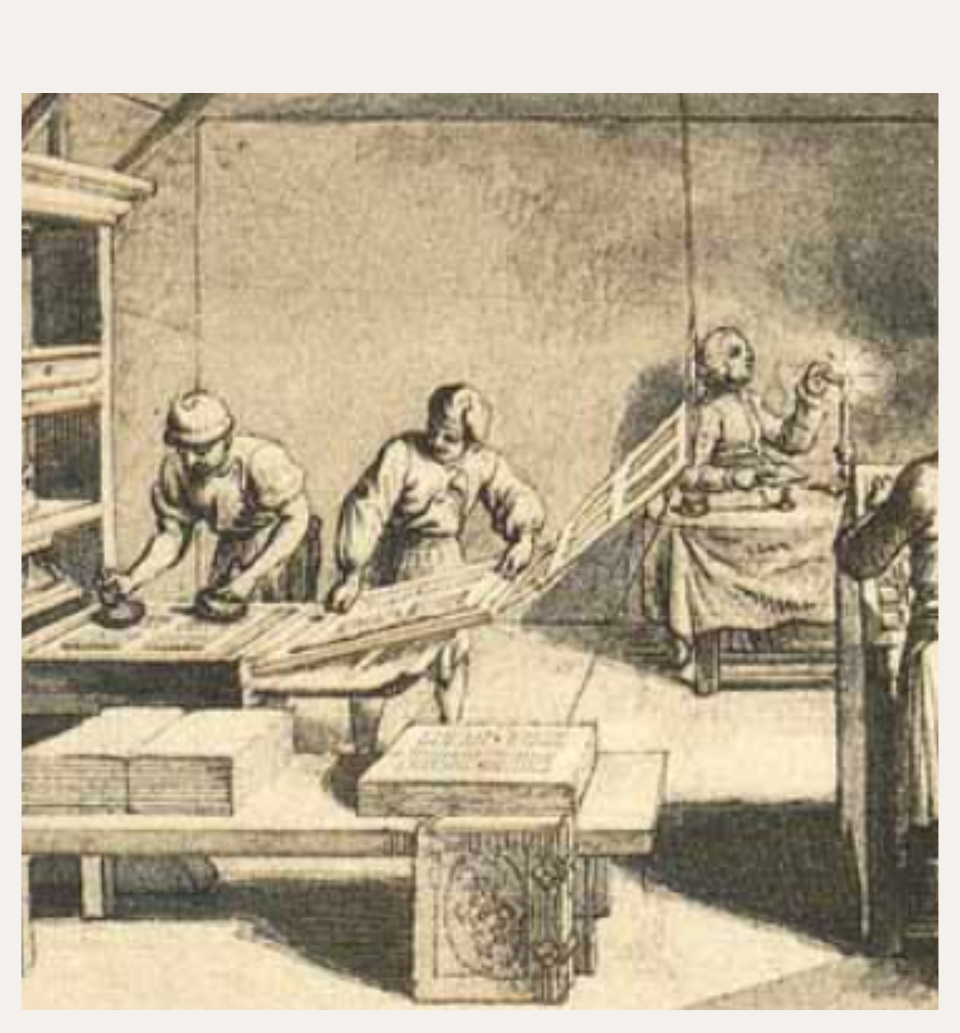

Screen printing first appeared in a recognizable form in China during the Song Dynasty (960–1279 AD).

It was then adapted by other Asian countries like Japan and was further created using newer methods.

The screen-printing process was largely introduced to Western Europe from Asia sometime in the late 18th century but did not gain large acceptance or use in Europe until silk mesh was more available for trade from the East and a profitable outlet for the medium discovered.

PROCESS OF SCREEN PRINTING - STEP 1: DESIGN CREATION

During the initial stage of the design process, a surface design is developed. Once the surface design is finalized, it is meticulously duplicated onto an acetate film which will serve as a stencil for the process of printing.

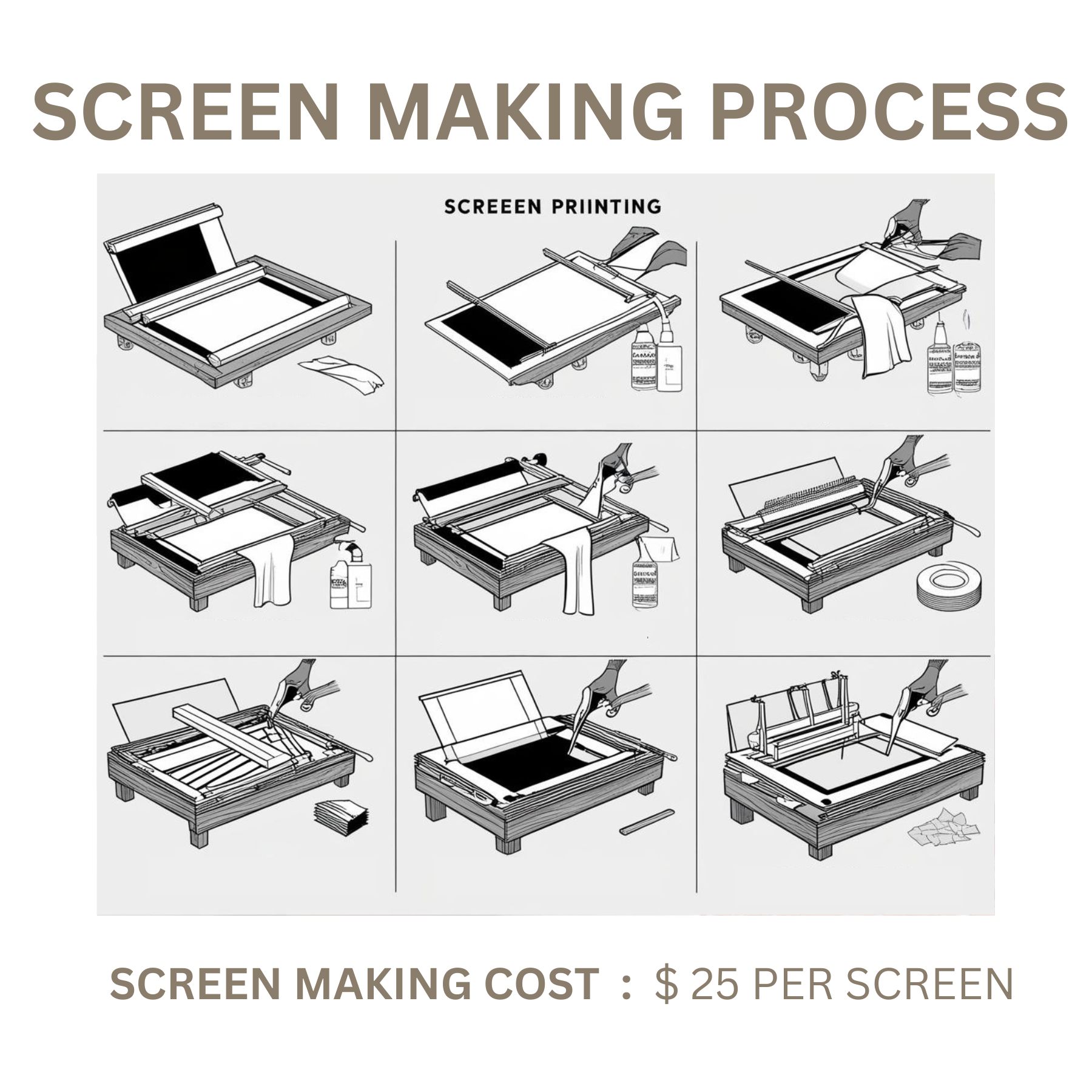

STEP 2: SCREEN PREPARATION

Next, the screen is prepared by selecting suitable mesh screen, taking into account the intricacy of the design and the fabric's texture. This is done to guarantee the best possible printing outcomes.

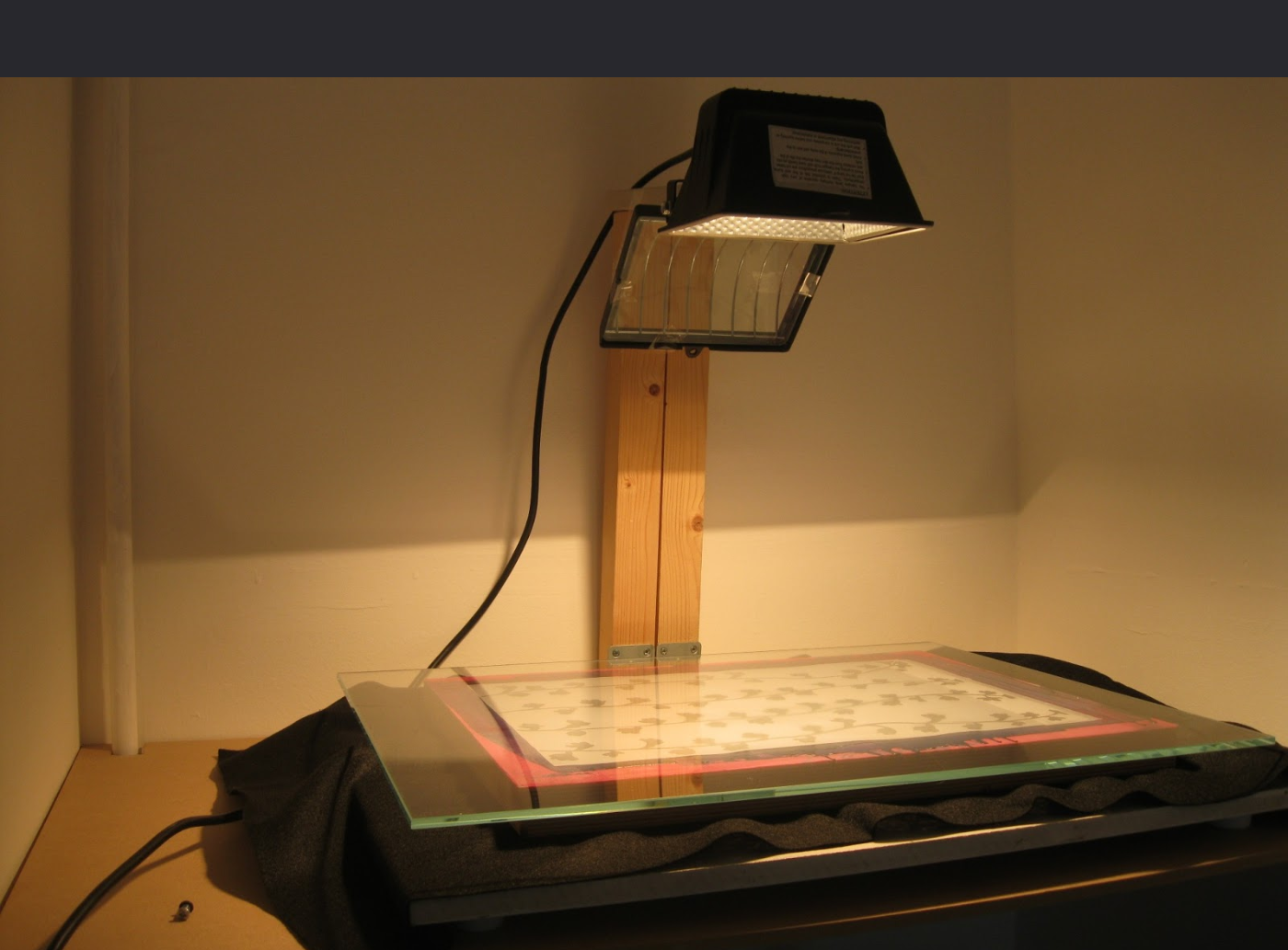

STEP 3: EMULSION EXPOSED FOR DRYING

The acetate sheet with the printed design is placed onto the screen covered with the light-sensitive emulsion. It is then exposed to intense light, causing the emulsion to solidify and form a stencil.

STEP 4: CLEANSING OF EMULSION

The unexposed, unhardened emulsion is rinsed away with precision, leaving behind a transparent imprint for the ink to flow through. Once any required corrections are made, the screen is dried and becomes ready for use.

STEP 5: PRINTING PROCESS

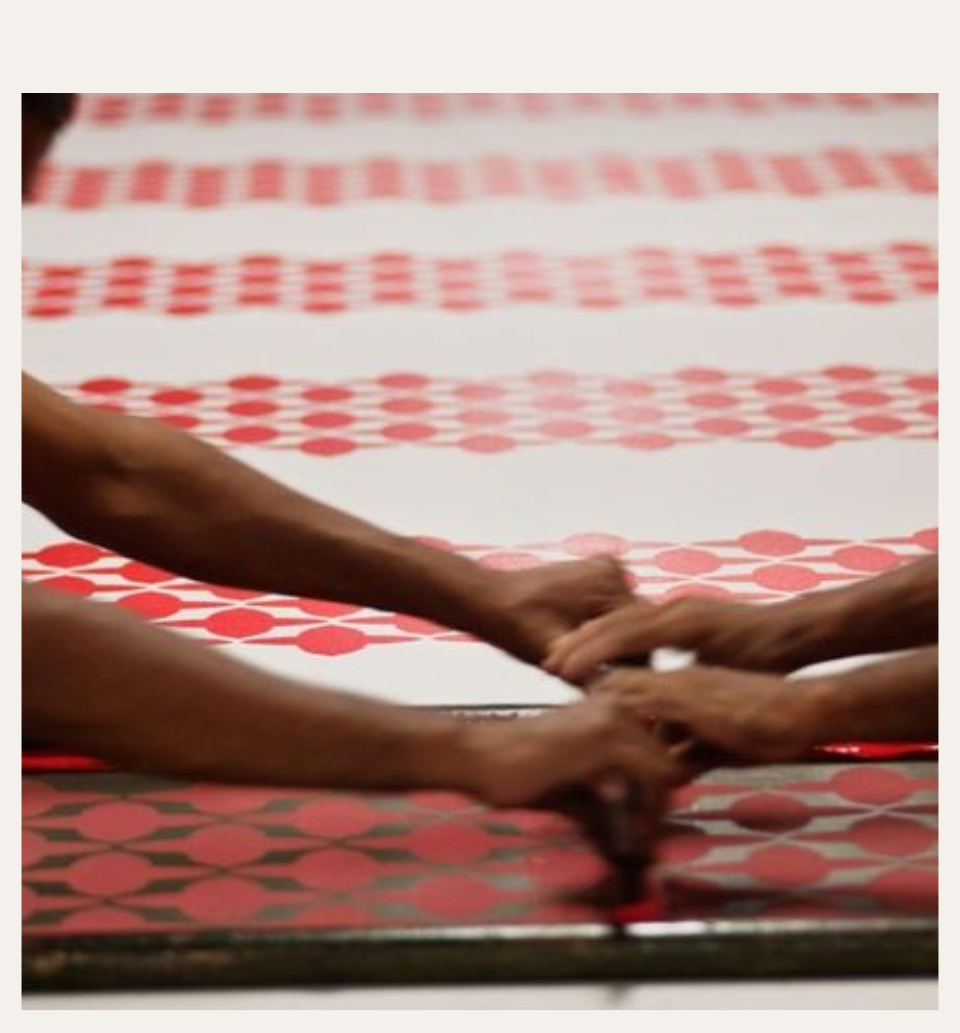

The fabric is placed flat, and a screen is lowered onto a board. Ink is applied to the top end, and a squeegee is utilized to drag the ink across the screen, pressing it through the open areas of the stencil and creating a design on the fabric.

STEP 6: FINISHING

The fabric with the printed design goes through a dryer that helps to set the ink and achieve a durable and vibrant color. Subsequently, it undergoes a thorough inspection and washing process to ensure that any remaining residue is completely removed.

TYPES OF SCREEN PRINTING

DIFFERENCE BETWEEN FLATBED PFRESS AND ROTARY SCREEN

A Flatbed Press is the most basic and least expensive option for screen printing. It uses a flatbed that holds the fabric screen printing onto the fabric. Because this process uses only one color at a time, each print will be darker than those made with other types of screens because they don't have access to all four colors in one pass as they do with rotary or cylinder presses.

A Rotary Screen utilizes revolving drums or cylindrical screens that hold color inside and apply it evenly against fabric surfaces when they roll during the printing process. This screen-printing process is more expensive than flat-bed screens because they require more complex machinery and higher quality parts and materials.

ADVANTAGES & DISADVANTAGES OF SCREEN PRINTING

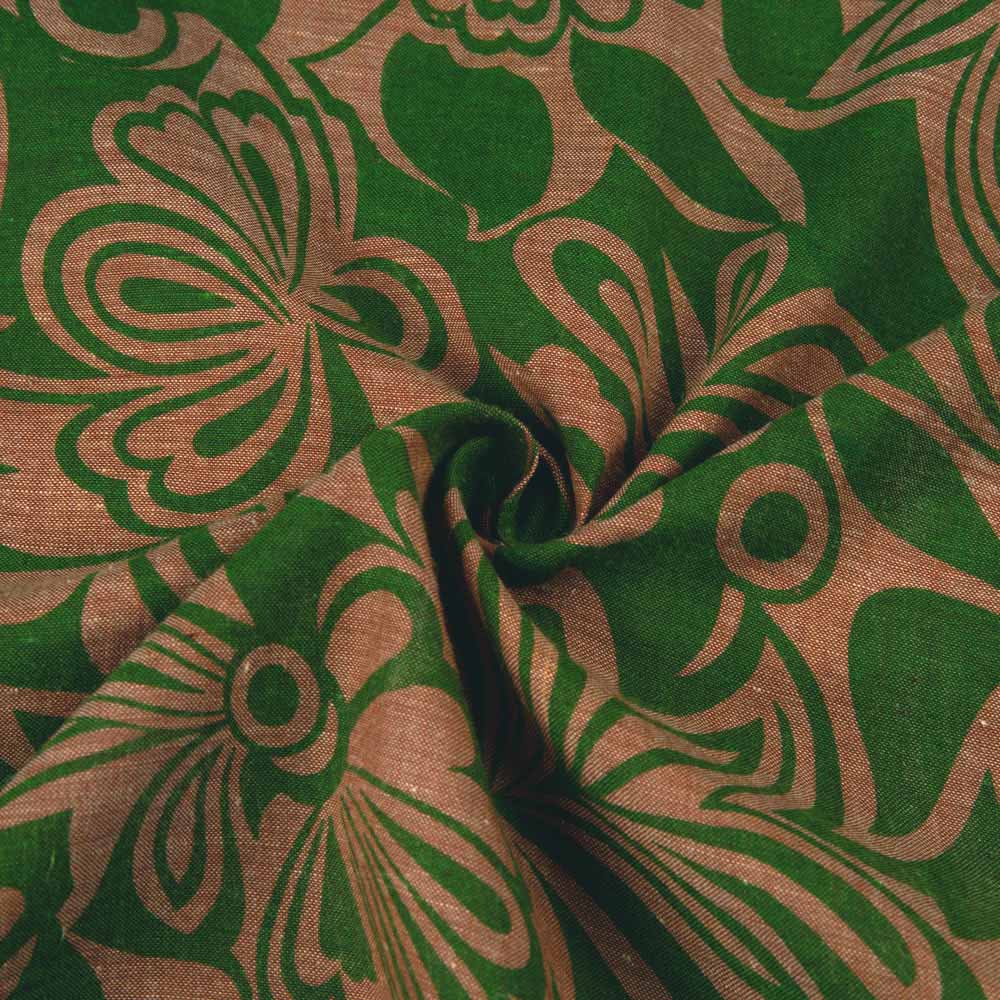

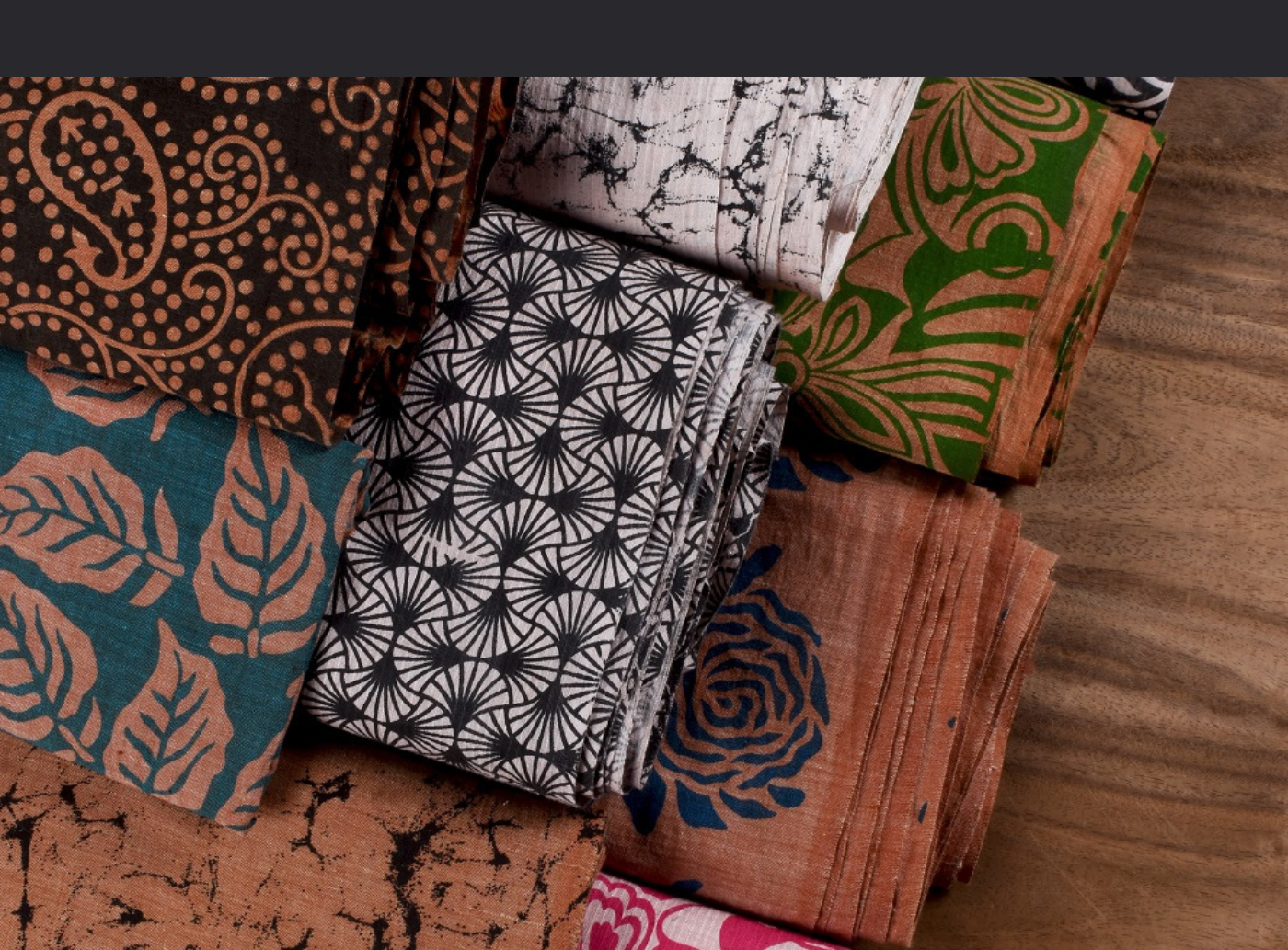

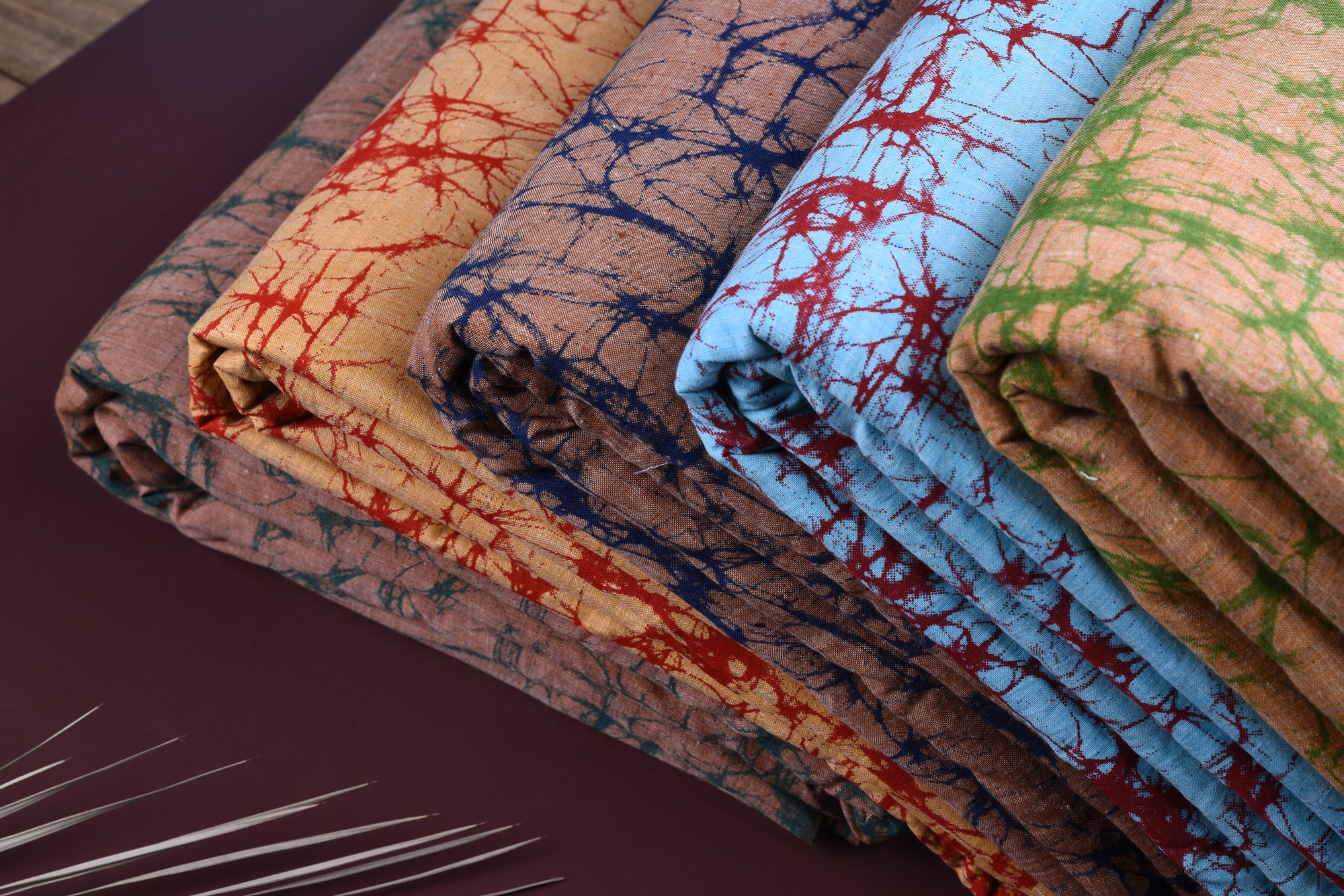

VISUALS OF SCREEN PRINTING

frequently asked questions

How much time does it take to screen print a meter of fabric?

arrow_drop_downThe printing time for a meter of Screenprinted fabric can vary depending on the intricacy of the design, no of layers to be printed and the expertise of the artisan. On average, it may take several hours to print a meter of this exquisite fabric.

Can I customize the motifs and designs for my Screen-printed fabric order?

arrow_drop_downYes, we offer customization options for Screen-printed fabrics. Our skilled artisans can work with you to create personalized designs and screens based on your preferences and requirements. Please contact us to discuss your customization needs.

How do I care for my Screen-printed fabric?

arrow_drop_downTo care for your fabric, it is recommended to wash it by hand using mild detergent and cold water. It is preferable to wash dark-colored fabrics separately. Bleach should not be used as it can potentially lead to cracking or fading. Hang the fabric in a shaded area for drying and while ironing, it is crucial to turn the fabric inside out to prevent any harm to printed areas.

What is the ideal application of Screen-printed fabrics?

arrow_drop_downScreenprinted fabrics are versatile, durable, and have a vibrant range of colors. They are perfect for creating designs on dresses, blouses, scarves, stoles, and home decor items like cushion covers and table runners. The range of colors and designs of Screen-printed fabric add a touch of elegance and uniqueness to any garment or accessory.

Is there a limit to the number of colors in a design?

arrow_drop_downEach color in a screen-printed design requires a separate screen. While there’s no strict limit, designs with fewer colors are more cost-effective and efficient to produce.

Are screen-printed designs durable?

arrow_drop_downYes, screen printing produces highly durable designs that resist fading, cracking, or peeling when cared for properly.

What makes screen printing unique?

arrow_drop_downScreen printing delivers vibrant, opaque prints that last. It’s ideal for bold, high-impact designs on both light and dark fabrics.

Can I see a sample before bulk production?

arrow_drop_downYes, we offer sample prints so you can review the design, colors, and quality before proceeding with a larger order.

More Stories

naturally dyed block printing

digital printing

hand block printing

handprinted batik

patachittra wall art

eri peace silk