How a Small Apparel Collection Gets Made, End to End

From the outside, producing an apparel collection often looks straightforward:

- Select a fabric,

- Finalize designs,

- Place an order,

- Receive finished garments.

In practice, especially when working with handwoven textiles and decentralized production, the process is more layered and sequential than it appears. This is a walkthrough of how one recent small apparel collection moved from brief to delivery at Anuprerna, outlining the decisions, constraints, and checkpoints involved at each stage.

We Create Together

Why This Collection Came to Us

The client was a slow-fashion womenswear brand preparing a limited seasonal collection for an international market.

They were looking for garments with a natural hand feel, visible textile character and heavy focus was put on embroidery work, while still meeting expectations around sizing consistency, repeatability, and construction quality.

Their requirements were specific:

- Small-batch production with the option to scale later

- Handwoven cotton suitable for everyday wear

- Clean construction aligned with international sizing standards

- Predictable timelines mapped to a retail calendar

They had previously experienced delays and inconsistencies when fabric sourcing and garment manufacturing were handled separately with other ethical, sustainable brands. The goal this time was to streamline the process and reduce friction between sampling and production.

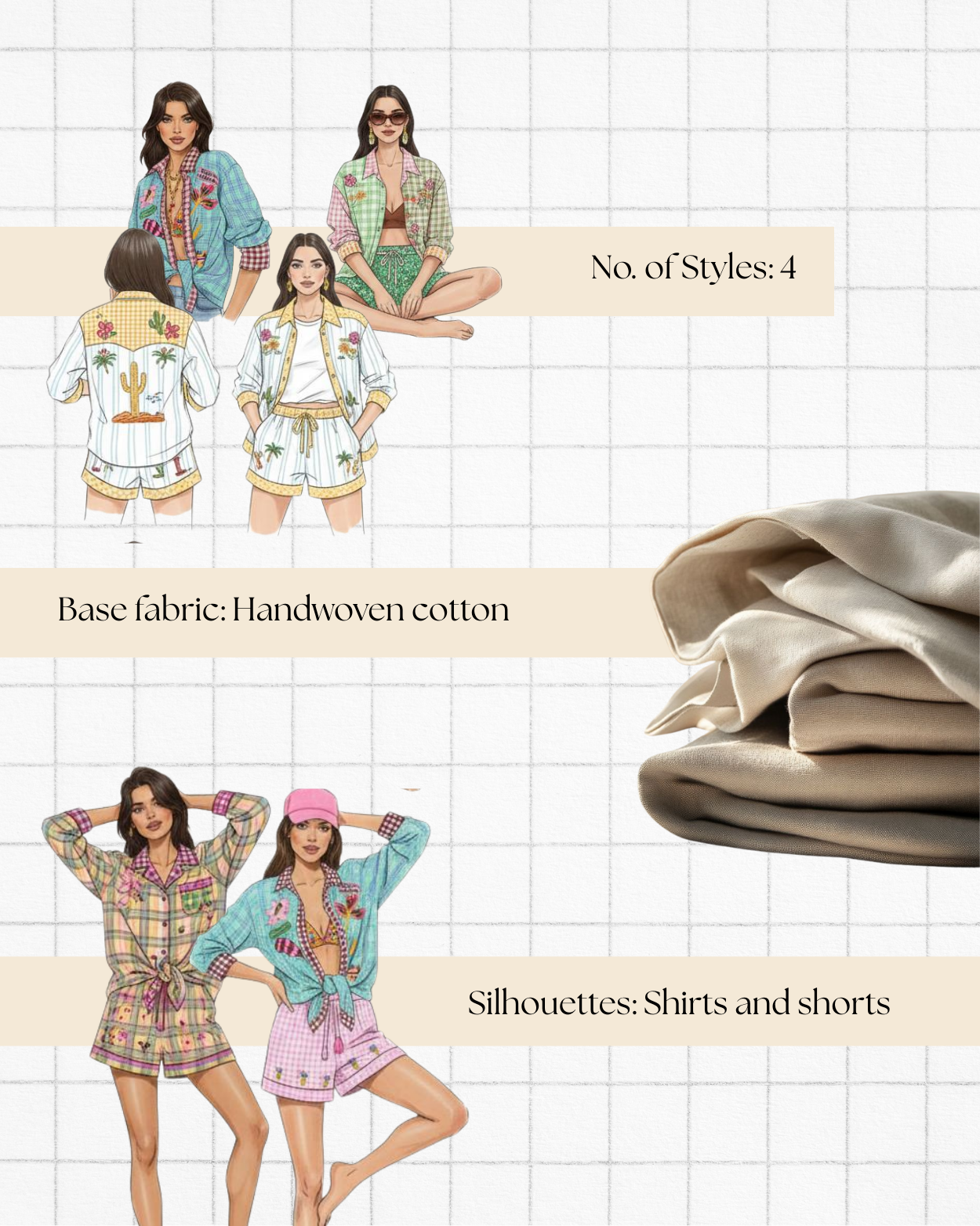

Collection Snapshot

- Category: Women’s ready-to-wear

- Number of styles: 4

- Total units: 20 garments

- Base fabric: Handwoven cotton

- Silhouettes: Shirts and shorts

- Market: Spain

- Production timeline: 6 weeks

At this scale, the margin for error is narrow. Decisions made during sampling directly affect production timelines and delivery reliability.

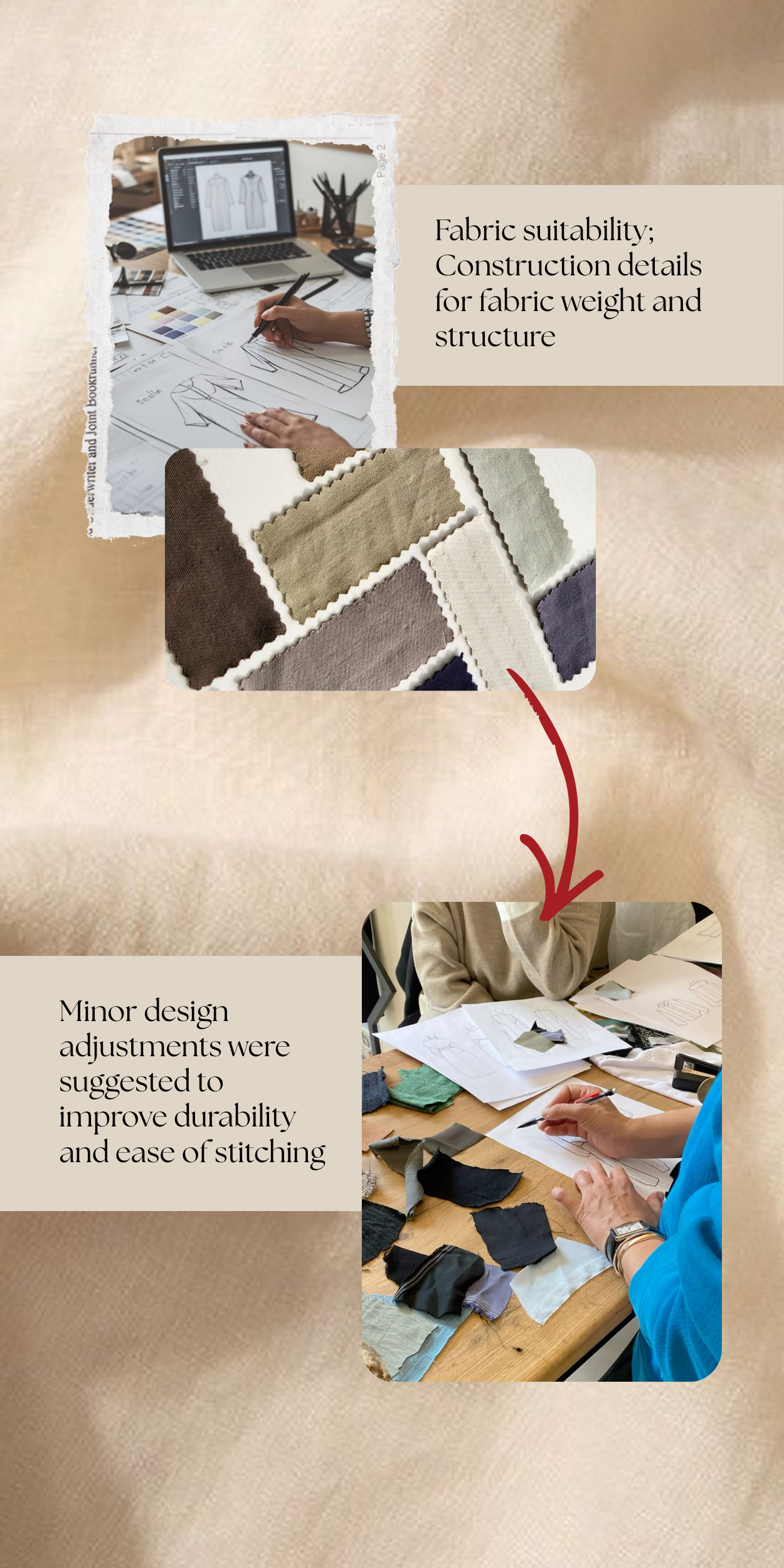

Design Finalisation and Fabric Alignment

The first step was aligning each silhouette with how the handwoven cotton would behave in wear and wash.

Not all handwoven fabrics respond the same way across different garment types, particularly when fit consistency is important.

The client provided initial sketches for all styles. Based on these:

- Fabric suitability was reviewed for each silhouette

- Construction details were assessed against fabric weight and structure

- Minor design adjustments were suggested to improve durability and ease of stitching

This stage ensured that design intent and material behaviour were aligned before sampling began.

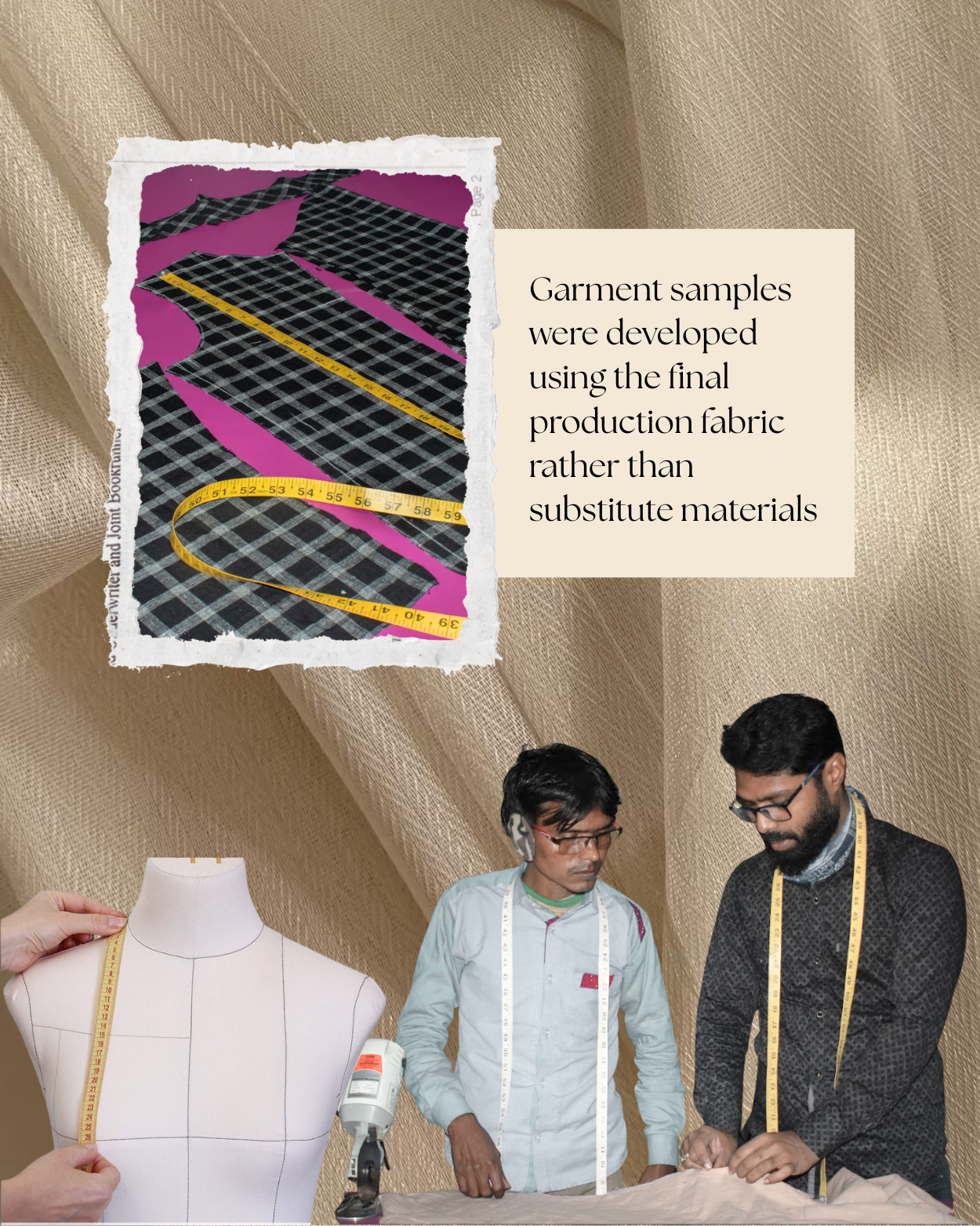

Sampling and Fit Corrections

Garment samples were developed using the final production fabric rather than substitute materials. This helped surface fabric-specific issues early, including minor shrinkage and balance differences in sleeves and hems.

Sizing was provided by the client and based on UK size standards. Fit corrections were documented style by style. Instead of freezing patterns immediately, one additional iteration was allowed for two key silhouettes where fabric behaviour changed slightly after washing and finishing.

This added time at the sampling stage, but it prevented production-level corrections later.

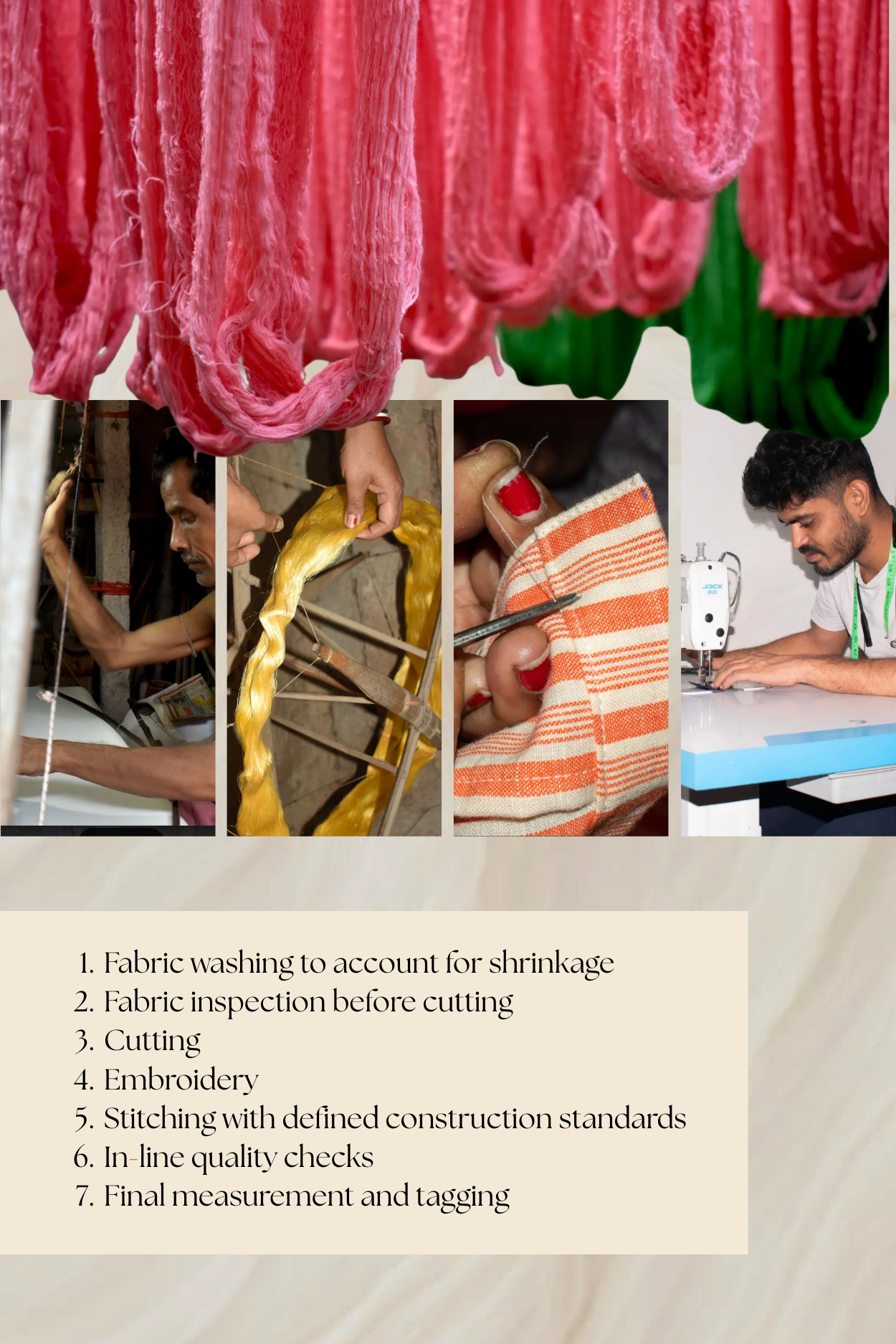

Making the Garments

Garment construction followed a controlled and sequential flow:

- Fabric washing to account for shrinkage

- Fabric inspection before cutting

- Cutting

- Embroidery

- Stitching with defined construction standards

- In-line quality checks

- Final measurement and tagging

Production was sequenced by style rather than executed all at once. This ensured that quality checks were meaningful and corrective action could be taken early if required.The focus throughout was consistency across sizes and finishes, not speed.The focus throughout was consistency across sizes and finishes, not speed.

Production Outcome and Delivery

All garments were delivered as approved during sampling. The client confirmed consistency across sizes and finishes, and the collection moved directly into retail without the need for additional alterations.

frequently asked questions

1. How long does it take to produce a small apparel collection?

arrow_drop_downProducing a small apparel collection typically takes 4 to 6 weeks, depending on the number of styles, sampling iterations, fabric preparation, and finishing requirements. When working with handwoven fabrics, additional time is often allocated for fabric washing, inspection, and fit corrections to ensure consistency across garments.

2. Is small-batch apparel production suitable for international brands?

arrow_drop_downYes, small-batch apparel production can work well for international brands when sizing standards, quality checks, and timelines are clearly defined upfront. Using documented sampling, controlled production stages, and final measurements helps ensure garments meet overseas market expectations without requiring post-delivery alterations.

3. Why is sampling important in handwoven apparel manufacturing?

arrow_drop_downSampling is critical in handwoven apparel manufacturing because fabric behaviour can vary after washing and finishing. Sampling with final production fabric allows issues related to shrinkage, fit balance, and construction to be identified early, reducing the risk of corrections during bulk production.