How a Small Handwoven Apparel Order Took Shape

From the outside, producing an apparel collection is often framed as a simple sequence: choose a fabric, finalise designs, place an order, receive finished garments.

In reality, that version only holds in fully industrial systems. When you are working with handwoven textiles and decentralized artisan production, every stage is interdependent and largely irreversible. Decisions made early around fabric behaviour, sizing and sequencing determine whether the collection moves smoothly or unravels later.

This piece walks through how one recent small apparel collection moved from brief to delivery at Anuprerna, focusing not on outcomes, but on the decisions, constraints and checkpoints that shaped the process at each stage.

Why This Collection Came To Us

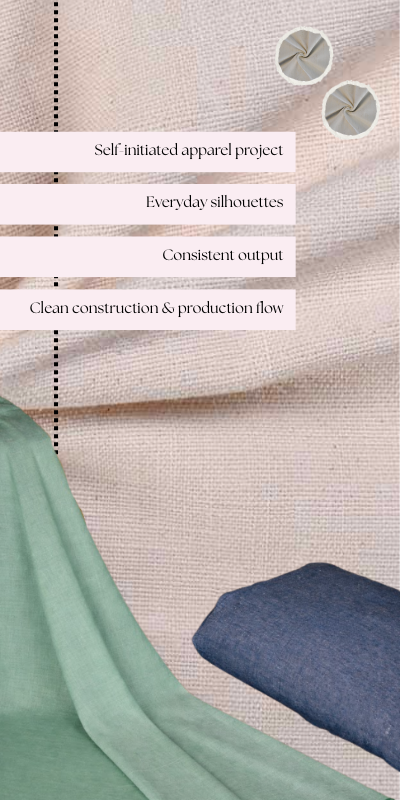

The client was an independent designer working on a self-initiated apparel project. He approached Anuprerna looking for a streamlined process that could support both fabric development and garment production within a single workflow.

The collection focused on khakee-coloured handwoven cotton, developed into everyday silhouettes such as Patiala pants and dhoti-style trousers. While the forms were simple, they depended heavily on fabric behaviour, drape, and balance.

His expectations were clear: consistent output despite handwoven variation, clean construction and a production flow where fabric performance was understood early rather than corrected later. Having faced delays when sourcing and manufacturing were handled separately in the past, the goal this time was to reduce friction between sampling and execution and build a process that could remain repeatable if the collection scaled.

Collection Snapshot

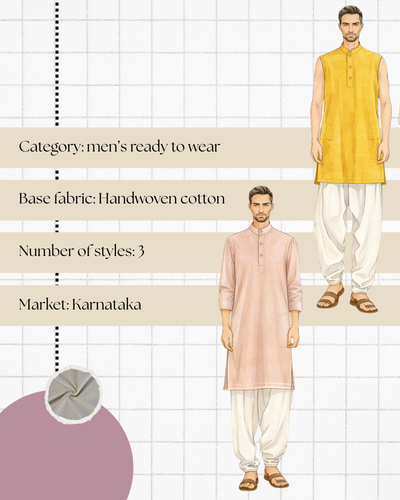

- Category: men’s ready to wear

- Number of styles: 3

- Total units: 09 garments

- Base fabric: Handwoven cotton

- Silhouettes: Dhoti pant, Collared Kurta, Patiala pant.

- Market: Karnataka

- Production timeline: 3-4 weeks

At this scale, there is little room for correction. Choices made during sampling directly determine production stability, timelines, and delivery confidence.

Design Finalisation and Fabric Alignment

The first step was aligning each silhouette with how the khakee handwoven cotton would behave in wear and wash.

While the fabric carried a natural hand feel, its weight, fall, and recovery needed to be evaluated differently for a dhoti pant, a Patiala pant, and a collared kurta, especially where volume and balance affect fit.

The client shared initial design references for all three styles. Based on these:

- Fabric behaviour was reviewed against each silhouette

- Construction methods were assessed for stitch stability and long-term wear

- Minor adjustments were suggested to improve movement, durability, and ease of execution

This stage ensured that the garment forms respected the material’s characteristics before sampling moved forward.

Sampling and Fit Corrections

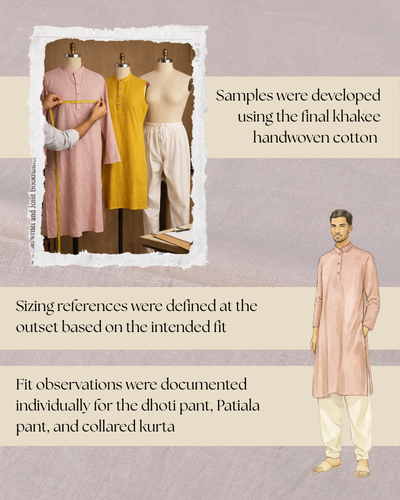

Garment samples were developed using the final khakee handwoven cotton selected for production, rather than alternate or substitute fabrics. This allowed fabric-specific behaviour to surface early, including minor shrinkage and changes in drape after washing.

Sizing references were defined at the outset based on the intended fit for each silhouette. Fit observations were documented individually for the dhoti pant, Patiala pant, and collared kurta. Instead of locking patterns immediately, one additional iteration was allowed where fabric response shifted slightly post-wash.

This extended the sampling phase marginally, but eliminated the need for corrective adjustments once production began.

Making the Garments

Garment construction followed a controlled, sequential flow:

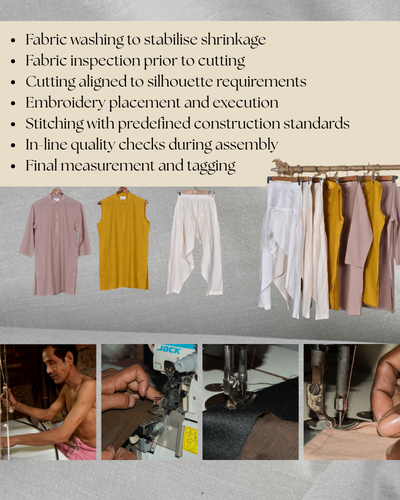

- Fabric washing to stabilise shrinkage

- Fabric inspection prior to cutting

- Cutting aligned to silhouette requirements

- Embroidery placement and execution

- Stitching with predefined construction standards

- In-line quality checks during assembly

- Final measurement and tagging

Production was sequenced by style rather than executed in parallel. This allowed quality checks to remain effective and adjustments to be made early where needed. Throughout the process, the priority remained consistency across fit and finish, not speed.

most asked questions

How does handwoven fabric impact production timelines?

arrow_drop_downHandwoven fabrics require washing, inspection, and stabilisation before cutting. These steps add time but ensure consistency and reliability, especially for garments where fit and drape matter.

Is this process scalable for larger collections?

arrow_drop_downYes, but only if the same decision discipline is maintained. Early fabric alignment, final-fabric sampling, and controlled sequencing are what make scaling possible without quality loss.

Why was final production fabric used during sampling?

arrow_drop_downHandwoven cotton behaves differently after washing and finishing. Using the final fabric during sampling allowed shrinkage, drape changes, and balance issues to surface early, avoiding corrections during production.

How were fit and sizing handled for this collection?

arrow_drop_downSizing was defined upfront based on the intended silhouette and wear style. Each garment was reviewed individually, and one additional iteration was allowed where fabric behaviour shifted post-wash.

Why was production sequenced by style instead of batching everything together?

arrow_drop_downSequencing by style allowed quality checks to remain meaningful. It made it possible to correct issues early without affecting the entire run, which is critical at small batch sizes.

More Stories

how a small apparel collection gets made, end to end

cynthia director

maria tolvanen