Banana Fiber: From Fruit To Fabric

Banana fiber, also known as musa textile fiber or Banana silk, is a natural fiber derived from the stems, leaves and peels of the banana plant. The stems and leaves are mechanically pulped then refined and mixed with other natural fibers or binders to improve its strength and texture. Their strength, durability, softness, and moisture-wicking capabilities make it an attractive choice for various textile applications.

Anuprerna is actively pursuing banana fiber and fabric as a strategic initiative aligned with our ethos of sustainability and dedication to quality. We believe in harnessing innovative and eco-friendly materials to enhance our product offerings while minimizing our environmental impact.

Origin and Significance

Banana fiber has a rich history rooted in various cultures worldwide. It was traditionally used in textiles for traditional garments, ceremonial robes, and artifacts. Banana fabric clothing products have gained popularity in recent years, offering a unique and eco-friendly alternative to conventional textiles. From clothing to home furnishings, banana fabric is making its mark in the fashion industry and beyond. The high content of banana fibers in the plant, along with the sustainable practices involved in its extraction, contribute to its status as a sustainable fabric.

Banana fiber, also known as musa textile fiber, is a natural fiber derived from the stems of the banana plant. It is widely recognized for its exceptional strength, durability, and eco-friendly characteristics. This versatile fiber has gained significant popularity in the textile industry due to its sustainable nature and impressive mechanical properties, making it an ideal choice for banana fiber cloth.

Banana as Sustainable Fiber Source

Ongoing research and future prospects for banana fiber along with other natural fibers focus on improving manufacturing techniques, blending with other fibers, chemical modifications, sustainable practices, nanotechnology applications, and meeting consumer demand. These efforts aim to enhance the quality, performance, and versatility of banana fiber, positioning it as a leading sustainable material for various industries. With a focus on sustainability and innovation, banana fiber holds promise for a brighter future in the textile industry.

Banana Fiber Extraction

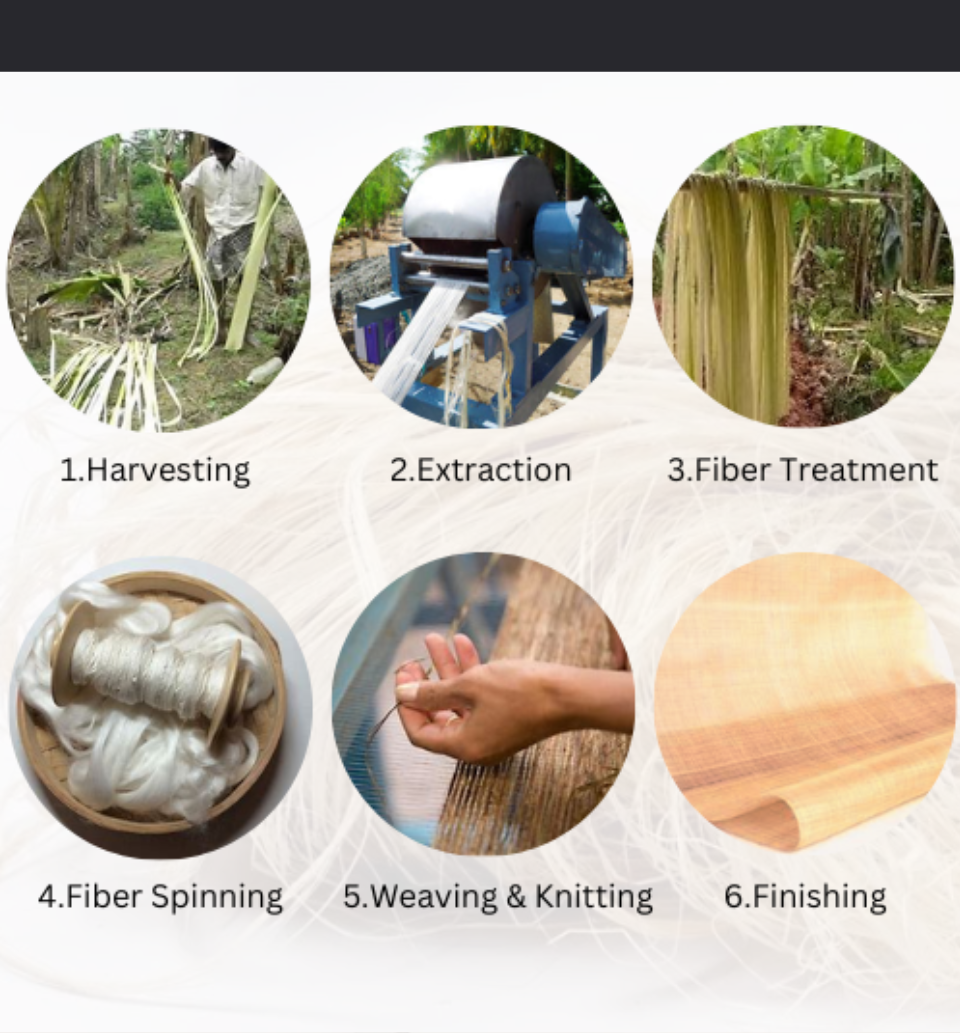

The manufacturing process of banana fiber involves several intricate steps.

Harvesting: Mature banana plants are carefully selected and harvested. The outer layers of the plant are removed, and the usable inner fibers are extracted.

Extraction: The extracted fibers undergo a process called decortication, where they are separated from the plant's stem. This can be done manually or by using mechanical decorticators.

Fiber Treatment: The extracted fibers are then washed thoroughly to remove impurities and dried to achieve the desired moisture content. This ensures the fibers are clean and ready for further processing.

Fiber Spinning: The dried banana fibers are spun into yarn using traditional or modern spinning techniques, depending on the desired end product. The yarn can be blended with other fibers to enhance its properties or used in its pure form.

Weaving/Knitting: The banana fiber yarn is woven or knitted into fabrics using traditional or advanced weaving/knitting machines.

Finishing: After weaving or knitting, the banana fiber fabric undergoes finishing processes such as dyeing, printing, and coating, depending on the desired functional properties of the end product.

Properties of Banana Fiber

Banana fiber exhibits a range of unique properties that make it a desirable material for various applications.

Strength and Durability: Banana fiber possesses remarkable tensile strength, surpassing that of other natural fibers such as cotton or jute. This attribute ensures that banana fiber products are long-lasting and resistant to wear and tear.

Lightweight: Despite its strength, banana fiber is relatively lightweight, making it suitable for a wide range of applications. This characteristic adds comfort and ease of use to the end products.

Softness: Banana fiber features a soft and smooth texture, providing a pleasant sensory experience when used in textiles. It offers a luxurious feel against the skin, making it a preferred choice for clothing and other personal accessories.

Moisture Absorption: With excellent moisture absorption properties, banana fiber can effectively wick away perspiration and maintain a dry and comfortable environment. This quality is particularly advantageous for sportswear and outdoor apparel.

Thermal Regulation: Banana fiber exhibits natural thermal regulation, allowing it to adapt to changing temperatures. It provides insulation during colder seasons and ensures breathability in warmer climates.

Applications of Banana Fabric

Textiles and Apparel: Banana fiber is utilized in the production of clothing, including shirts, dresses, and saris. Its softness, strength, and moisture-wicking properties make it an excellent choice for comfortable and sustainable clothing options.

Home Furnishings: Banana fiber is woven into rugs, carpets, curtains, and upholstery fabrics, adding an organic and eco-friendly touch to interior spaces. Its durability ensures these furnishings can withstand daily use.

Handicrafts: Artisans incorporate banana fiber into various handicrafts such as bags, baskets, and decorative items. Its natural appeal and strength make it a favored material for creating unique and sustainable pieces.

Paper and Packaging: Banana fiber can be processed into paper, providing an eco-friendly alternative to conventional paper production. Additionally, its strength and tear resistance make it suitable for packaging materials.

Eco-friendly Products: The sustainable nature of banana fiber makes it an ideal choice for eco-friendly products. From biodegradable packaging to compostable textiles, banana fiber contributes to a greener future.

banana fabric

Where can I find fabrics made from banana fiber?

arrow_drop_downFabrics made from banana fiber can be found in specialty stores, eco-friendly boutiques, and online platforms like Anuprerna

Which country is the largest producer of banana fiber today?

arrow_drop_downIndia stands as the foremost producer of banana fiber today, with a significant banana cultivation industry of 28.4 million tonnes per year.

How do I care for banana fabric?

arrow_drop_downBanana fabric is typically hand-washable or machine-washable on a gentle cycle. Use mild detergents and air drying is preferred over machine drying to maintain its integrity. Get more details on how to care for banana fabric and other natural fabrics here.

What are the applications of banana fiber in home decor?

arrow_drop_downBanana fiber can be used to create lampshades, curtains, and table runners, napkins enhancing the aesthetic appeal of homes and eco-friendly spaces

Can banana fabric be dyed in various colors?

arrow_drop_downYes, banana fabric can be dyed in a range of colors using natural or eco-friendly dyes. The fibers have good dye absorption properties, resulting in vibrant and long-lasting hues.

More Blogs

bengal looms for men: beyond the kurta

jamdani magic: why this weave is unesco-recognized as cultural heritage

weaving geography: which district is known for which handloom fabrics

the ultimate guide to naturally dyed and block printing textiles

why skin-friendly textiles are the next luxury in fashion

7 visual cues to identify fabric quality instantly