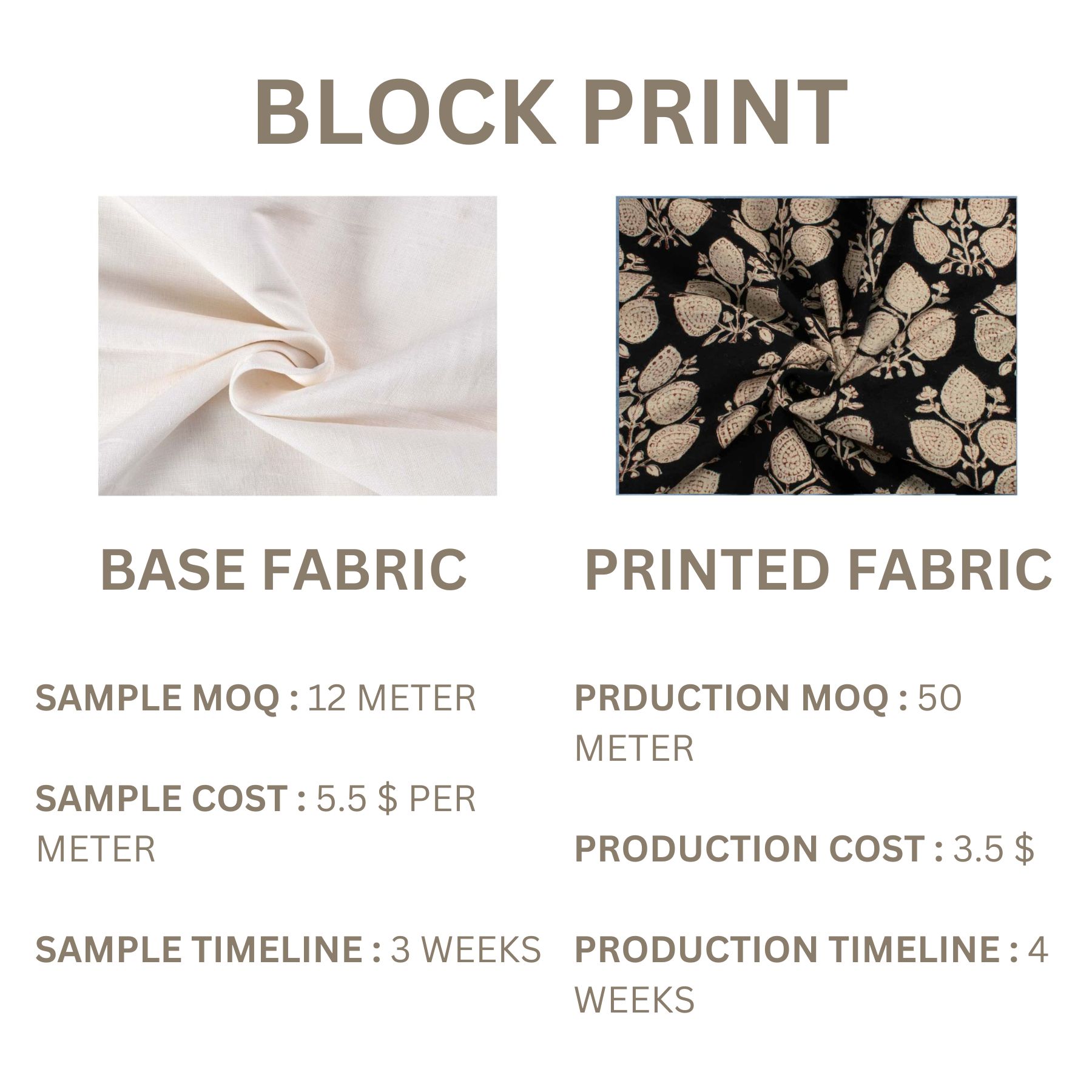

HAND BLOCK PRINTING

Woodblock Printing (Or Block Printing) Is A Technique For Printing Text, Images Or Patterns On Textiles And Later Paper. As A Method Of Printing On Cloth, The Earliest Surviving Examples From China Date To Before 220 AD. This Is The Oldest And Simplest Method Of Printing A Fabric. Still Extensively Used In Indian Cottage Industries, Block Printing Involves The Use Of Carved Blocks For Transfer Of Colour.

INTRODUCTION

Woodblock printing or block printing is a technique for printing used widely in East Asia. This is the oldest and perhaps the simplest method of fabric printing. India is one of the world's largest manufacturers and exporters of block-printed fabric. Still extensively used in Indian Cottage Industries, block printing involves using carved blocks to transfer color. A variation of the wooden blocks is the metallic blocks made with copper.

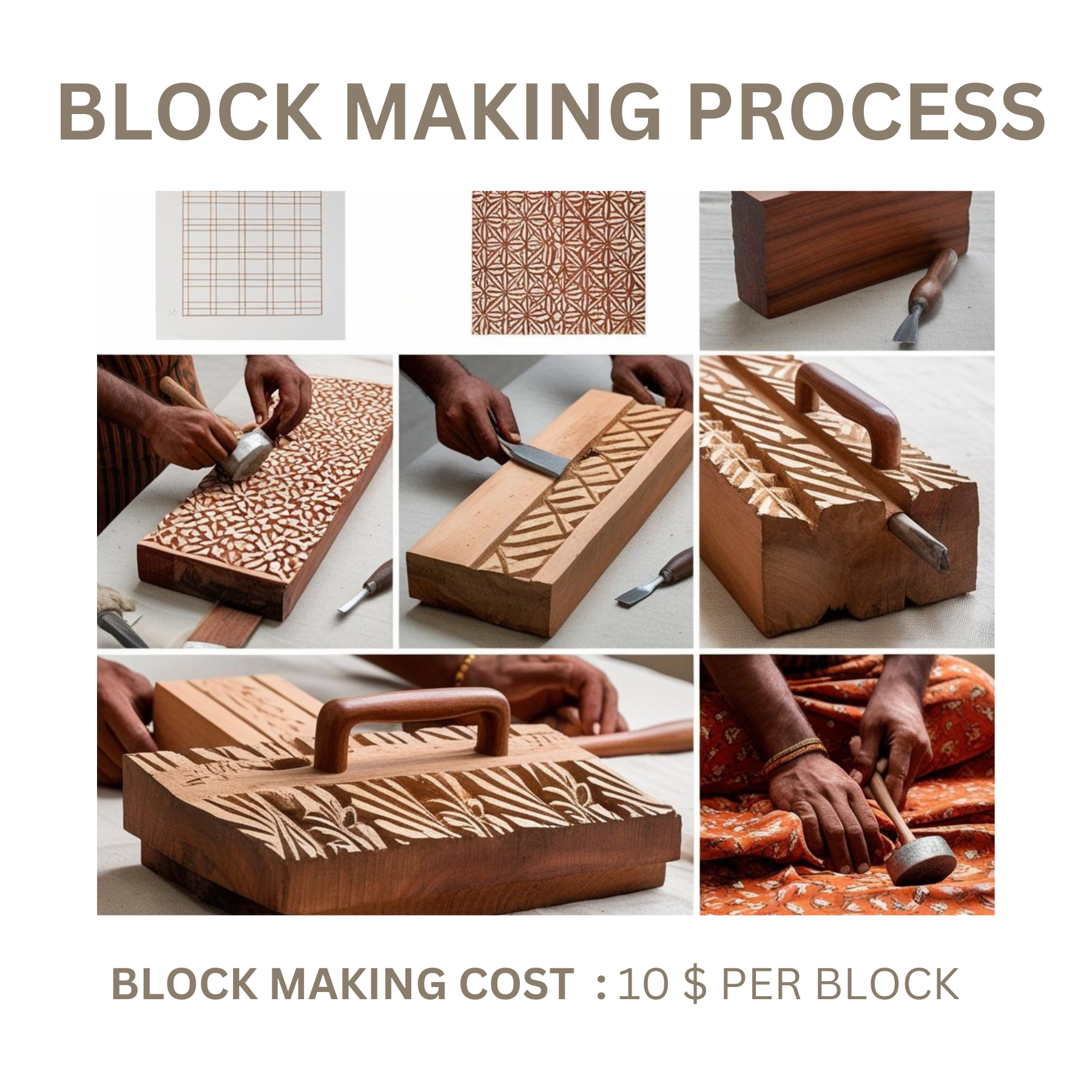

Blockmaking requires skills and patience. Even the use of blocks needs expertise since the color uptake on the fabric and matching of various blocks depend on the pressure and positioning of the blocks. Though block-printed fabrics are slow to produce, it ranks high on exclusivity.

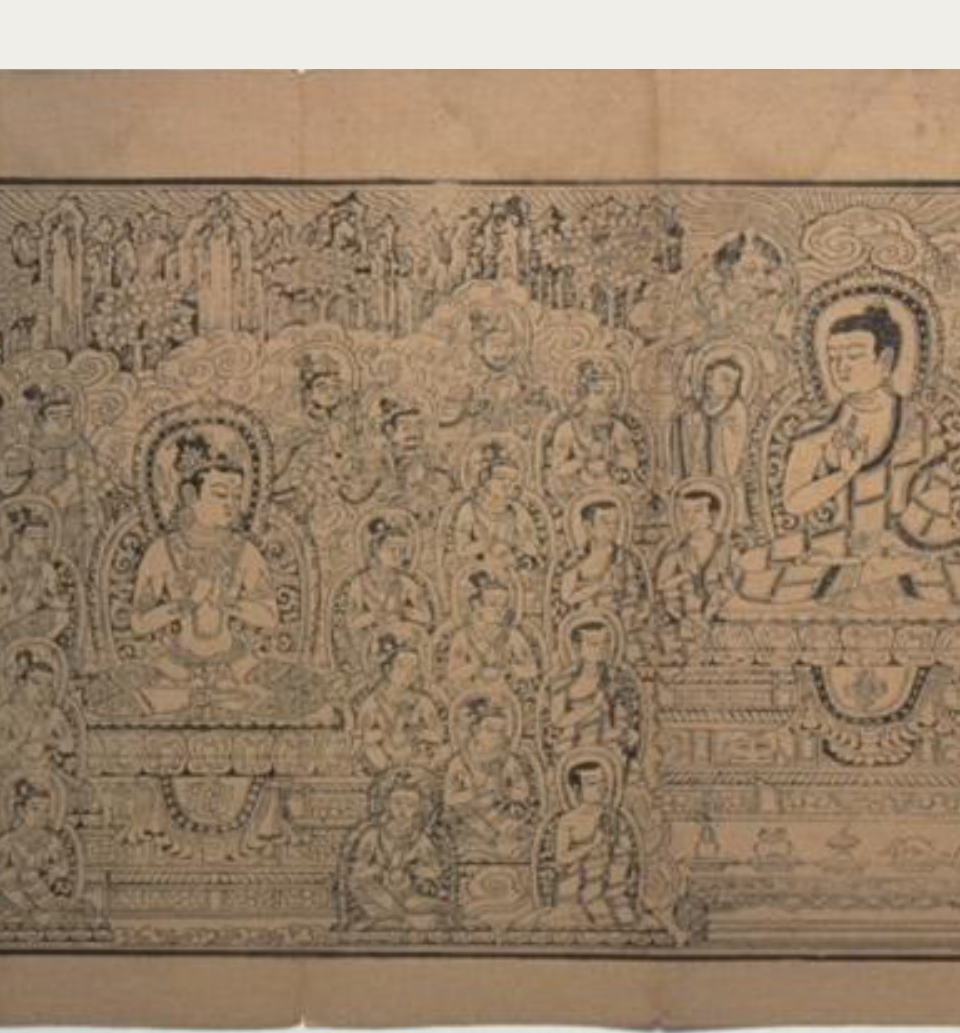

HISTORY

The earliest woodblock printed fragments, to survive are from China and are of Silk, printed with flowers in three colors from the Han Dynasty (before AD 220).

Woodblock printing existed in Tang China during the 7th century AD and remained the most common East Asian method of printing books and other texts. as well as images until the 19th century.

It is clear that woodblock printing developed in Asia several centuries before Europe.

WOODBLOCK PRINTING PROCESS

Woodblock Printing Process

STEP 1: PREPARING WOOD BLOCKS

The process starts by cutting out wooden pieces with a height of approximately 2-3 inches. Next, the design is traced onto the wood and the surrounding areas are carefully removed. To further enhance the wood's flexibility, the pieces are then soaked in oil for a period of 10-15 days.

STEP 2: PREPARING THE FABRIC

Initially, the fabric is cleansed to eliminate any starch present. If the fabric has been dyed previously, it is further washed to eliminate any surplus color. Following this, the fabric is left to dry under the sun. The dried fabric is carefully stretched over the printing table and firmly fastened using pins.

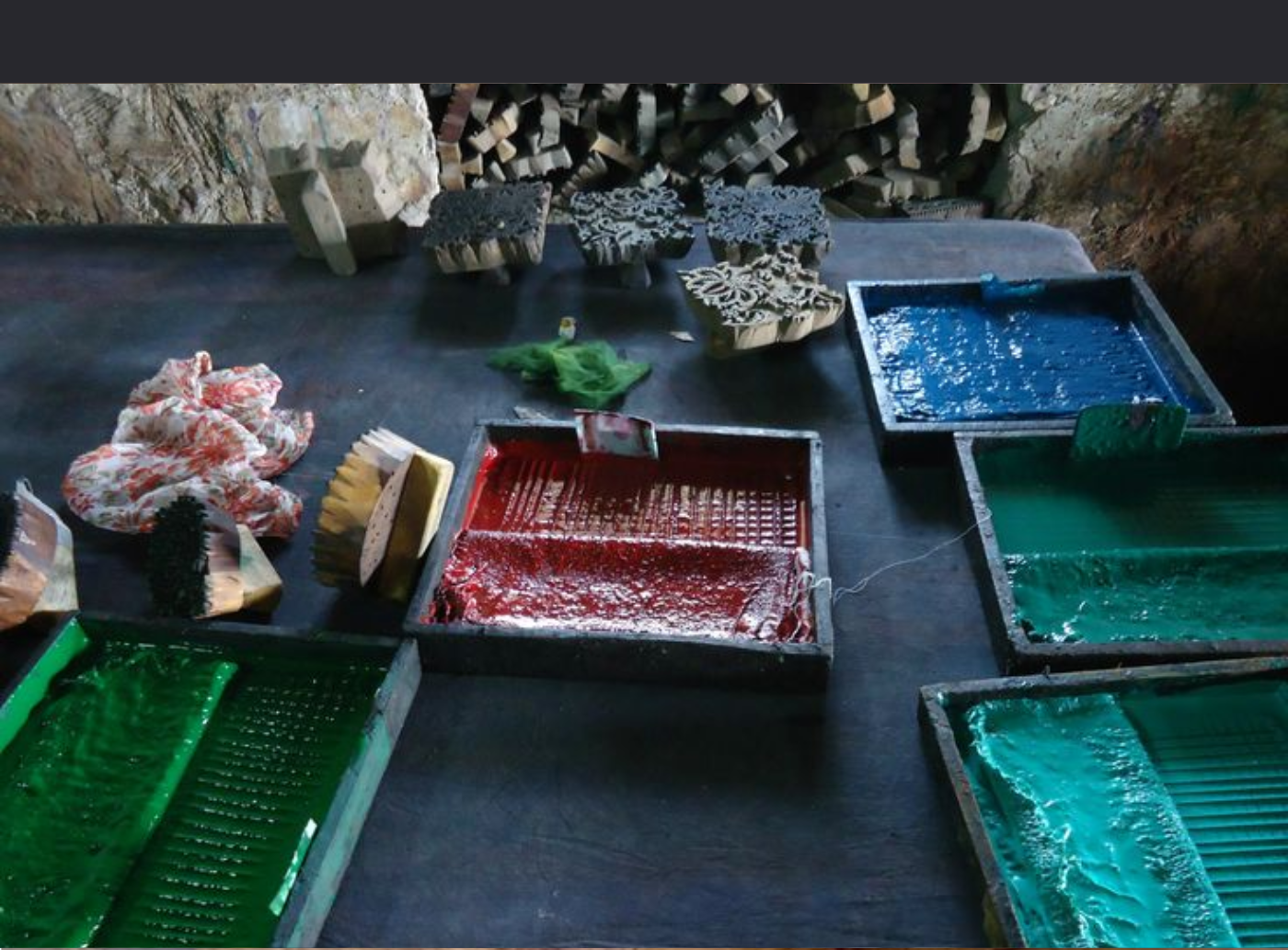

STEP 3: PRINT PASTE

The print paste pigment, blender, and fixer are combined, resulting in a mixture. This mixture is then transferred onto a tray, which is covered with either a jute cloth or a sponge sheet to guarantee a uniform spread. Next, a block is applied onto the surface of the print paste to absorb it.

STEP 4: PRINTING

The process of printing starts by ensuring an even distribution of color on the printing tray. Next, the block is dipped into the outline color and carefully positioned on the fabric. A firm press with the fist is applied to ensure a crisp impression. Following this, the blocks are utilized to apply the remaining colors.

(If the design repeat consists of five colors, then five blocks, each containing a segment of the design, will be necessary).

STEP 5: FINISHING

After the printing process, the fabric is exposed to sunlight to dry. Subsequently, it is carefully wrapped in newspaper to prevent the layers from sticking together. Following this, the fabric undergoes steaming and washing before being set aside to dry. Finally, ironing the fabric to complete the process.

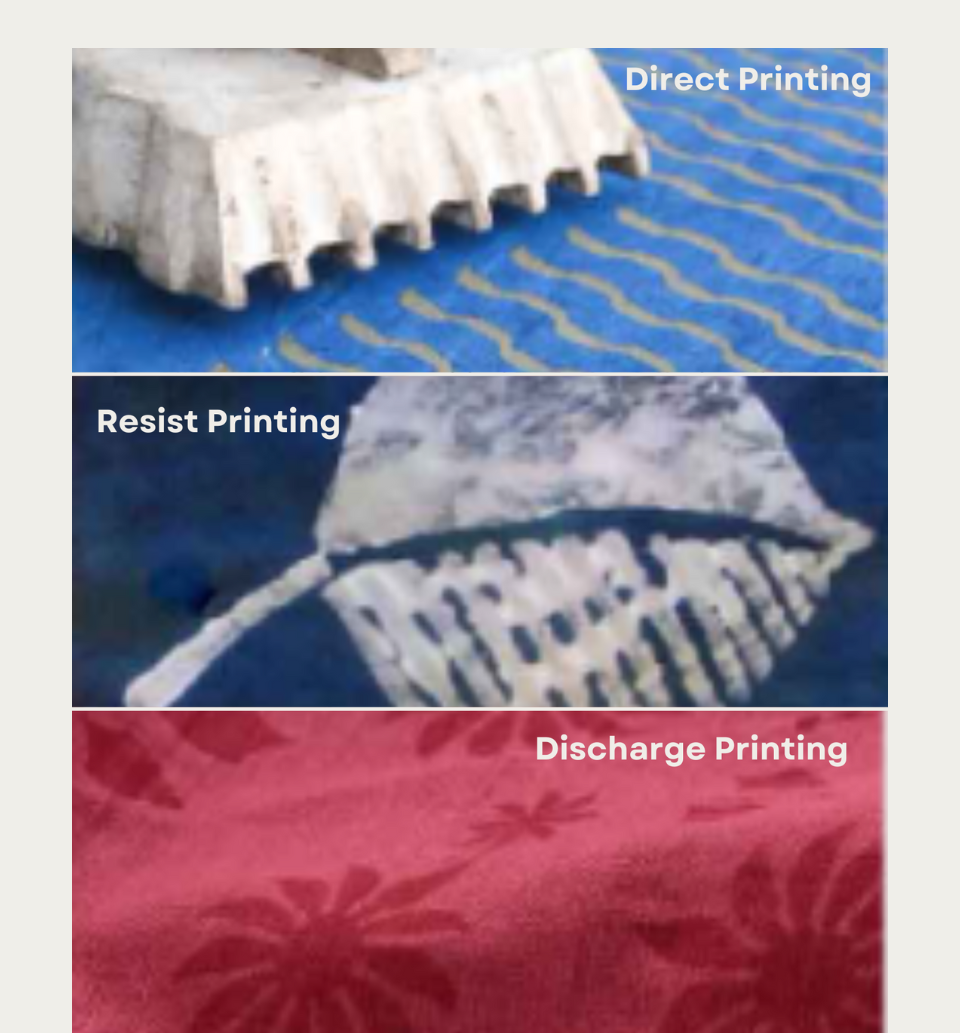

TECHNIQUES OF BLOCK PRINTING

Direct Printing: This method involves the bleaching of cotton or silk fabric initially, followed by dyeing and printing using engraved blocks. The process begins with using blocks to create the outline, and then subsequently applying blocks to fill in the colors.

Resist Printing: In the resist technique, specific regions that should remain dye-free are shielded using a combination of clay and resin. Afterward, the dyed fabric goes through a washing process, causing the dye to seep into the shielded areas through cracks, resulting in a ripple-like pattern.

Discharge Printing: In this method, the fabric is initially colored with dye. Then, a specific chemical is applied to eliminate the dye from the areas intended for different color designs. These treated portions are then prepared to be re-colored.

LOCATION:

Block printing, which was not originally native to West Bengal, was introduced to the region in the beginning of 20th century. Since then, the talented block printing artists of Bengal have developed their own unique designs, while still drawing inspiration from traditional motifs. Serampur, located in West Bengal, has emerged as the hub of block printing in the region, renowned for its striking and lively patterns.

The Art of Natural Dye Block Printing: A Timeless Craft

Natural Dye Block Printing is a sustainable art form that uses eco-friendly dyes from plants like indigo and turmeric, minerals like iron and alum, and insects like lac. Fabric is mordanted, stamped with hand-carved blocks, and cured for vibrant, unique, and timeless designs, embracing nature and craftsmanship.

Sustainability, tradition, and artistry—woven together in every print.

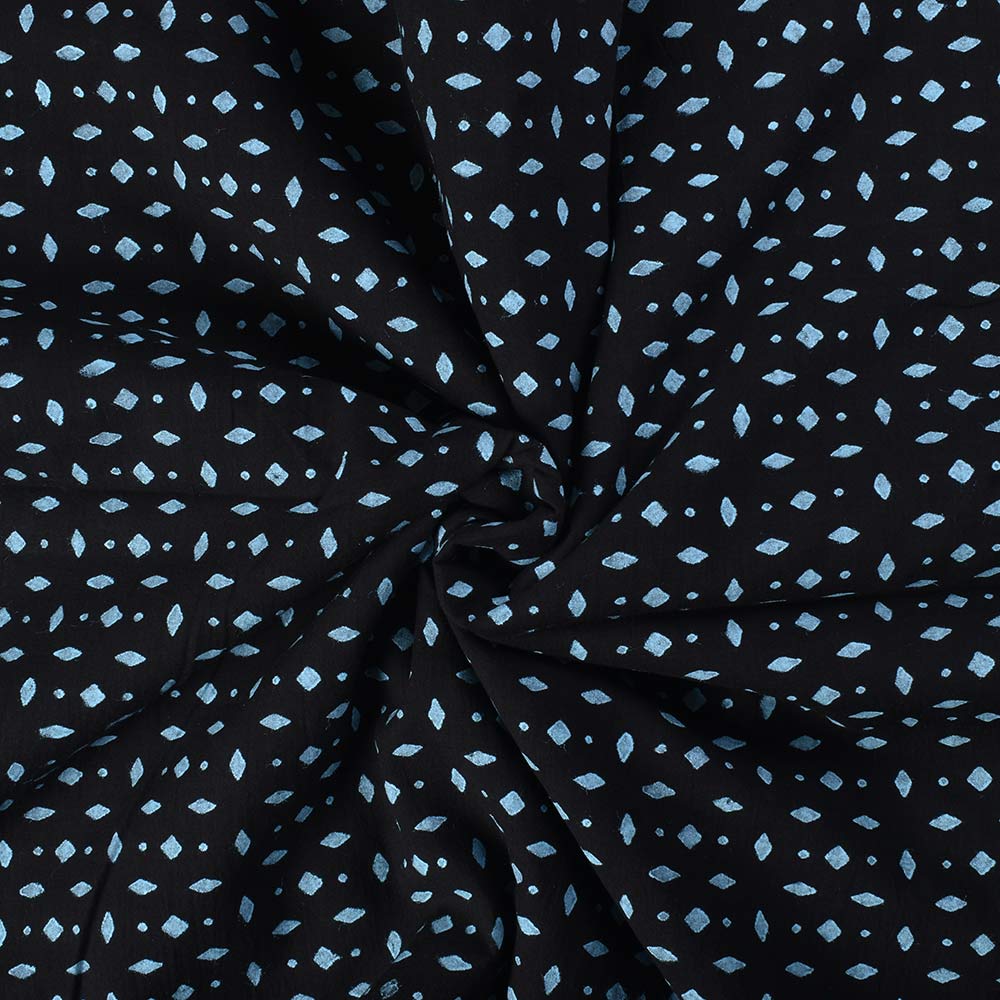

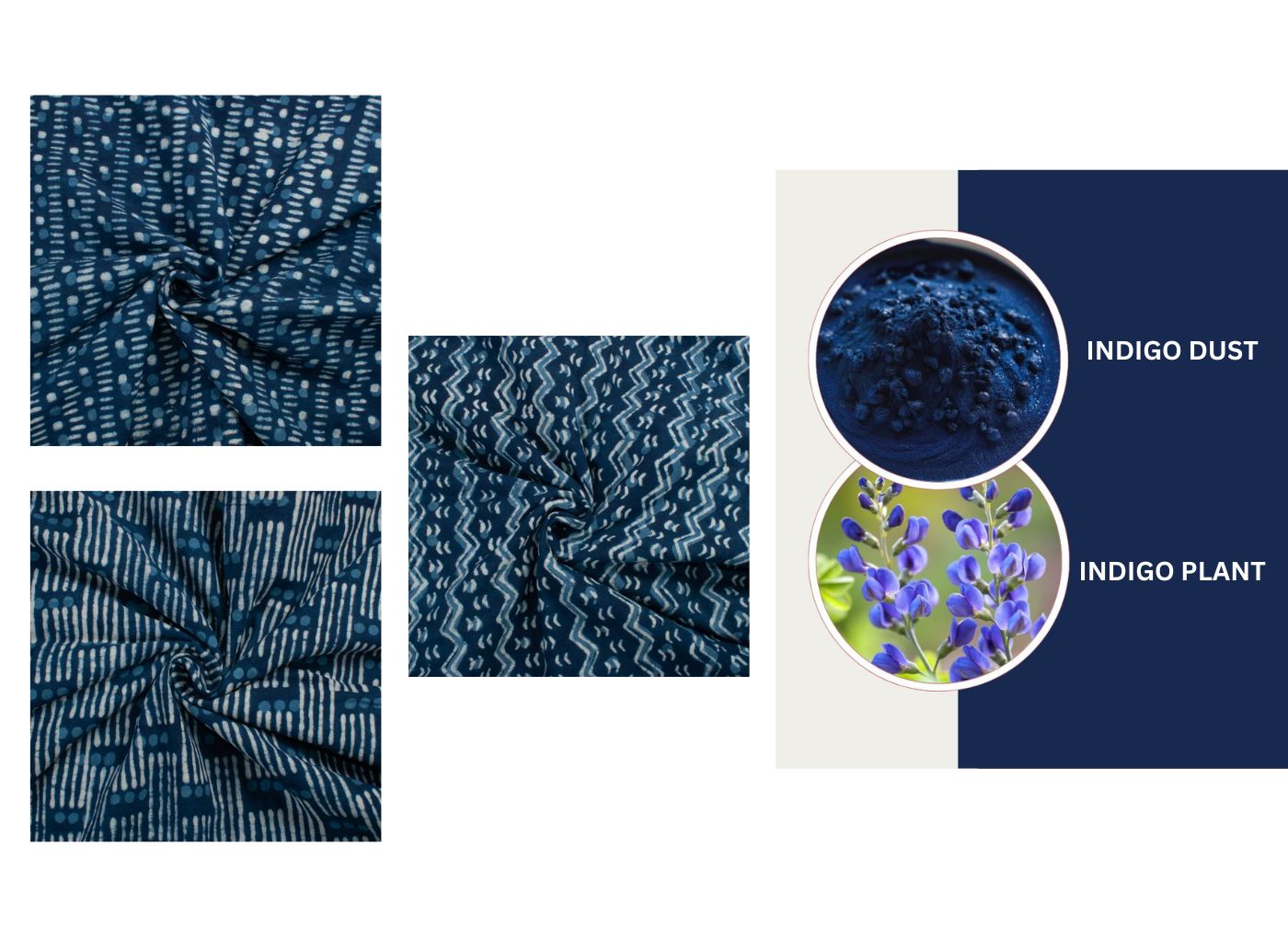

NAURAL INDIGO BLOCK PRINTS

- Natural indigo block printing is an eco-friendly process involving the use of natural indigo dye derived from Indigofera plants.

- Fabrics are pre-treated with natural mordants (e.g., alum) for better dye absorption

- Iron on low heat to avoid damage.

- Fabrics are dipped in indigo dye vats multiple times to achieve deep blue tones

NATURAL MARI GOLD BLOCK PRINTS

- Fresh marigold flowers are collected. The petals are the primary source of the natural dye

- The petals are simmered in water, strained to remove solids, leaving a vibrant yellow or orange dye.

- A mordant, such as alum, is used to fix the dye, ensuring better color adherence and longevity on the fabric.

- The printed fabric is immersed in the marigold dye bath, and the stamped areas resist the color, creating patterns.

- Set dye with heat, dry in shade.

NATURAL TURMERIC BLOCK PRINTS

- Turmeric Dye Paste: Prepare with turmeric powder, water, and a natural binder.

- Treat fabric with alum (bright yellow) or iron (greenish-yellow).

- Enhance dye absorption through ironing or steaming

- Produces bright yellow hues with sustainable techniques.

- Soak, dry, and rinse before printing

NATURAL IRON RUST BLOCK PRINTS

- Iron Dust Paste made from iron dust (rusted iron), water, and a natural binder like gum arabic or rice starch.

- Mix iron dust with water and binder to create a smooth, thick paste.

- Soak fabric in tannin solution (from plant sources like myrobalan or pomegranate peel)

- Produces rich, long-lasting hues like black, gray, or brown through iron-tannin reactions.

MADDER ROOT (RUBIA TINCTORUM)

- Soak dried madder roots overnight.

- Simmer them in water to extract the red dye.

- Madder Root Produces shades of red, from soft pink to deep crimson,

- depending on the mordant used.

- Mix the liquid dye with dissolved Babool gum to form a thick paste

- Babool gum stabilizes dye on fabric, ensuring even absorption and enhancing color intensity.

- Dry in the shade to preserve the vibrant red color

VISUALS OF BLOCK PRINTING

frequently asked questions

What types of fabrics are commonly used for hand block printing?

arrow_drop_downHand block printing can be done on a variety of fabrics, but it is most commonly seen on cotton, silk, linen, and other natural fibers. These fabrics readily absorb the dyes used in the printing process.

What are some common applications of hand block printed fabrics?

arrow_drop_downHand-block printed fabrics are versatile and widely used in multiple industries. They are especially favored in the fashion industry, where they are employed to design garments such as dresses, tunics, scarves, and traditional attire. Additionally, these fabrics are extensively utilized for home furnishings, including bedspreads, curtains, and cushion covers. They also find applications in creating accessories, upholstery, and various do-it-yourself crafts.

Are hand block printed fabrics colorfast, or do they fade over time?

arrow_drop_downhe colorfastness of hand block printed fabrics depends on various factors, including the quality of dyes used and the care taken during printing. While some fading may occur over time with repeated washing and exposure to sunlight, proper care can help maintain the colors.

Are there specific care instructions for hand block printed fabrics?

arrow_drop_downYes, to prevent color bleeding, it is advisable to wash hand block printed fabrics separately or with like colors for the first few washes. Using cold water and a mild detergent can help maintain the colors. When storing hand block printed fabrics, ensure they are clean and dry. Store them in a cool, dry place away from direct sunlight to prevent color fading. When ironing, use a low to medium heat setting.

Can I customize designs for block printing?

arrow_drop_downYes, we can create custom wooden blocks based on your design. Simply share your artwork, and we’ll ensure it’s carved into a block for printing.

Is block printing eco-friendly?

arrow_drop_downYes, block printing is a sustainable method that uses minimal energy and eco-friendly dyes. It supports artisanal craftsmanship and generates less waste compared to industrial printing methods.

More Stories

naturally dyed block printing

digital printing

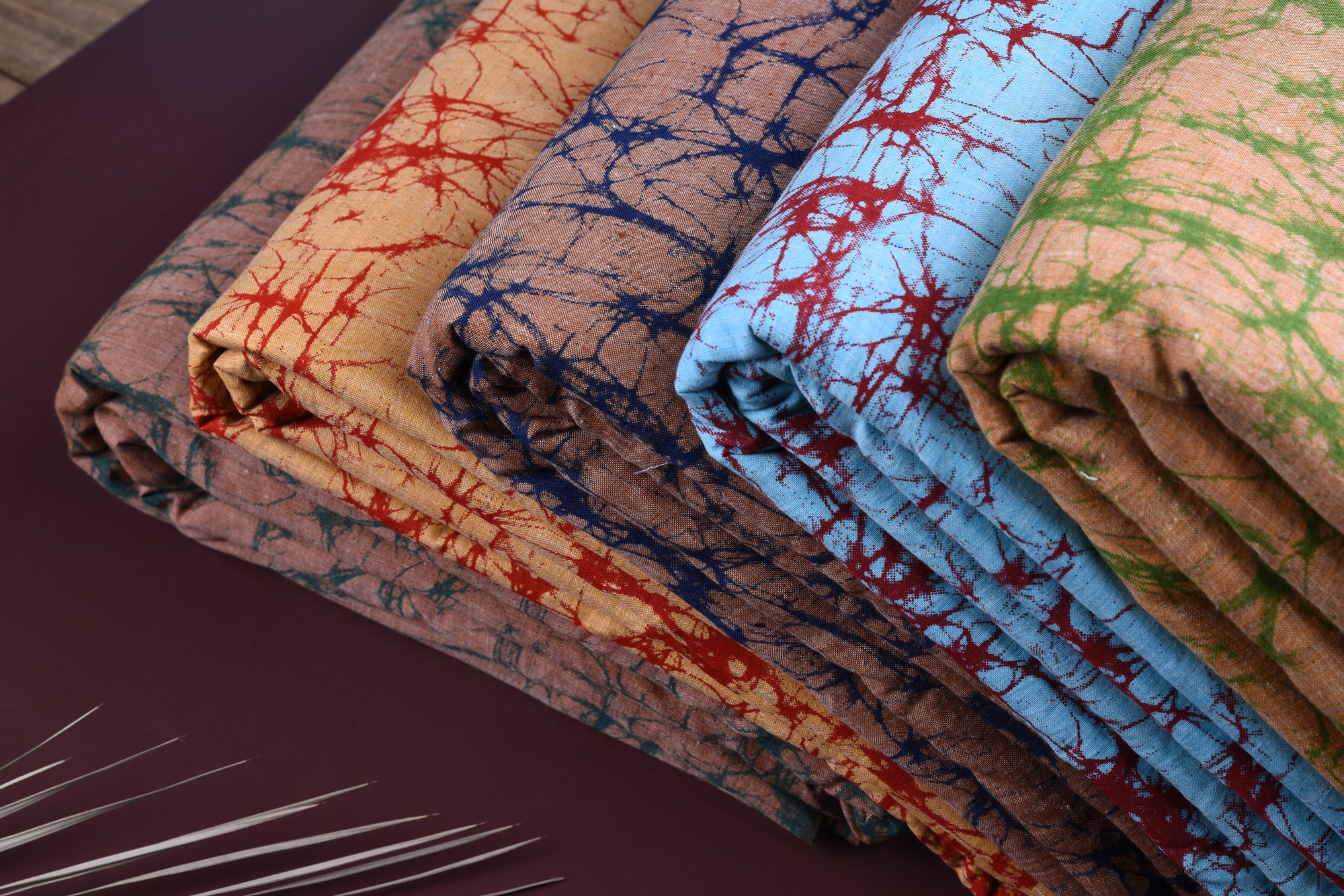

handprinted batik

screen printing

ikat - a distinctive style

piece dyed fabrics