Digital printing

Digital printing has transformed the landscape of printing, offering unparalleled precision, flexibility, and efficiency in the production of various materials, including textiles. Unlike traditional printing methods, which often involve complex setup processes and limited design options, digital printing allows for seamless integration of intricate patterns, vibrant colors, and customizable designs with minimal effort.

History

In the 1970s, the introduction of inkjet printing technology laid the foundation for modern digital printing. Inkjet printers utilized tiny nozzles to spray droplets of ink onto paper or other substrates, offering a more versatile and cost-effective alternative to traditional printing methods. This development paved the way for the emergence of digital textile printing.

Process Involved - Design Preparation

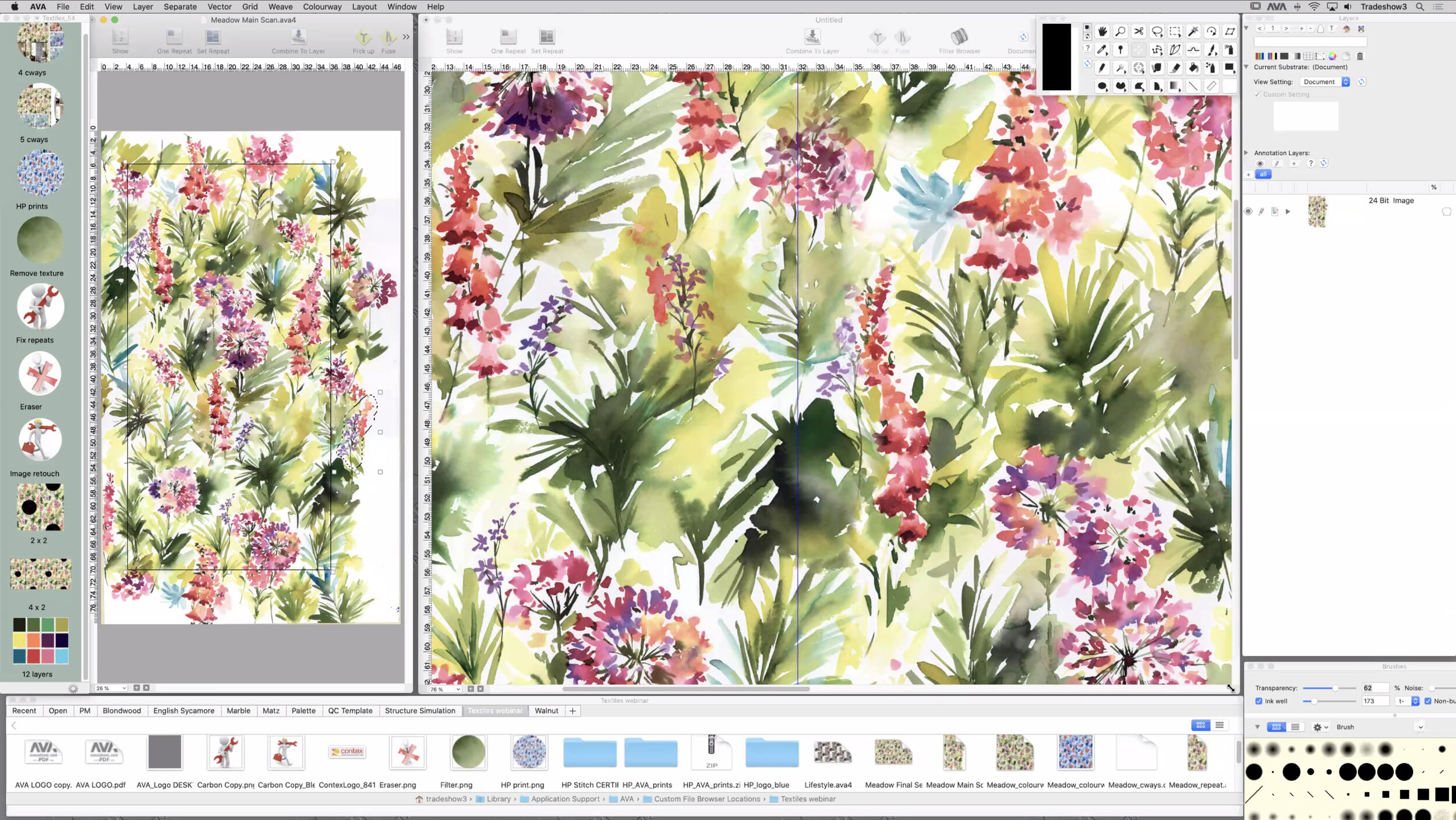

The first step in digital fabric printing is to prepare the digital design or artwork. Designers use graphic design software such as Adobe Photoshop or Illustrator to create or modify the design according to the desired specifications. The design may include patterns, colors, images, or text.

Color Separation

If the design contains multiple colors, it may need to undergo color separation. This process involves breaking down the design into individual color components to create separate files for each color. Color separation ensures accurate color reproduction during the printing process.

Printing Setup

The prepared design files are then loaded into the digital printing software or RIP (raster image processor). The printer settings, such as ink type, print resolution, and fabric type, are configured based on the desired output. Additionally, the fabric is prepared for printing by ensuring it is properly aligned and secured on the printing bed.

Printing

With the setup complete, the digital printing process begins. The printer applies ink directly onto the fabric surface according to the instructions provided by the design files. Depending on the printer technology (e.g., inkjet or dye-sublimation), the ink may be applied in one pass or multiple passes to achieve the desired color intensity and saturation.

Drying and Fixation

After printing, the fabric needs to undergo a drying and fixation process to set the ink and ensure colorfastness. This may involve heat curing, steam fixation, or chemical treatments, depending on the ink and fabric type used. Proper fixation is essential to prevent color bleeding or fading over time.

Finishing

Once the fabric is dry and the ink is fixed, it may undergo additional finishing processes to enhance its appearance or performance. This may include washing to remove excess ink or finishing treatments such as softening or coating to improve texture or durability.

Why opt for Digital printed fabrics?

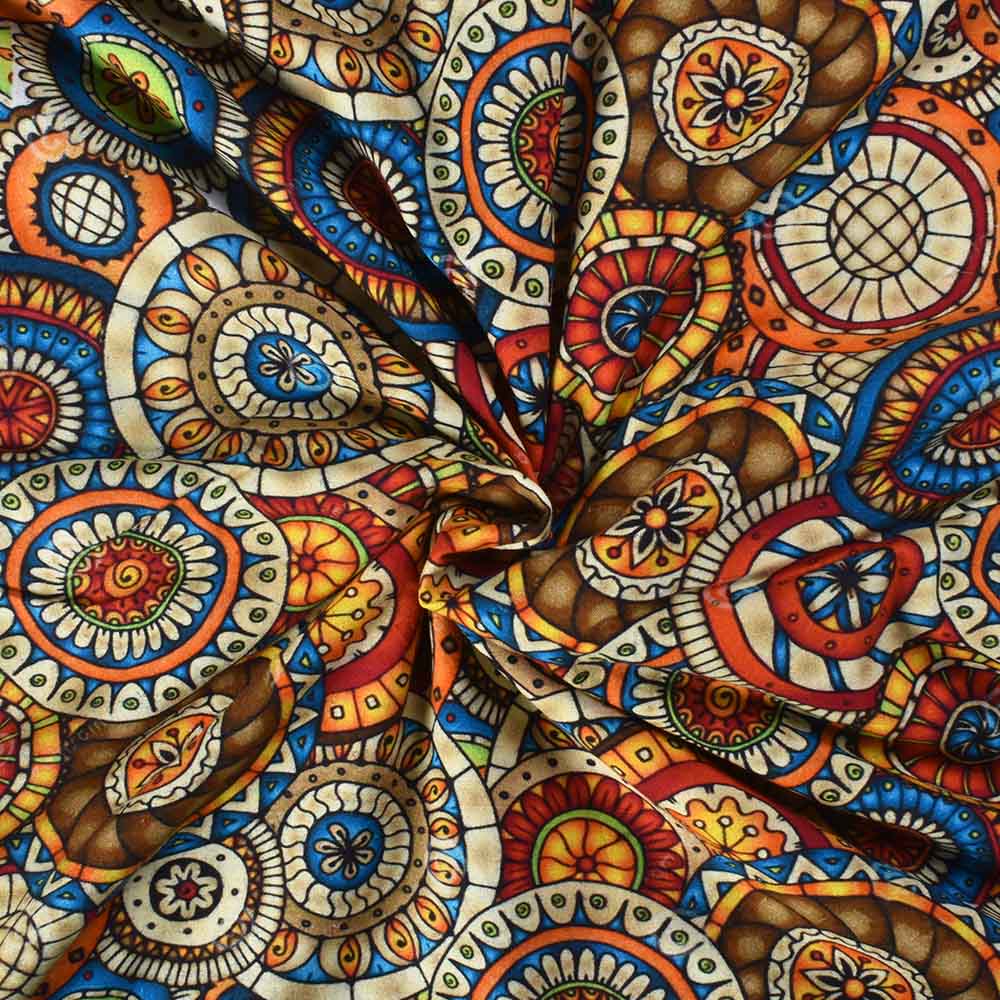

- Versatility :Digital printing allows for the printing of intricate designs, vibrant colors, and complex patterns on a wide range of fabric types, including cotton, polyester, silk, and linen.

- Customization: Digital printing offers unparalleled customization options, allowing designers to create unique and personalized fabric designs tailored to specific customer preferences or project requirements.

- High-Quality Reproduction: Digital printing technology enables high-resolution printing, ensuring sharp and precise reproduction of intricate details, textures, and color gradients.

- Environmentally Friendly: Digital printing produces minimal waste compared to traditional printing methods, as it eliminates the need for screens, plates, and excess ink.

related questions

Can I print custom designs?

arrow_drop_downYes, we specialize in printing custom designs provided by our clients. Whether it's artwork, patterns, or logos, we can bring your vision to life.

What are the care instructions for digitally printed fabric?

arrow_drop_downHand wash or machine wash on a gentle cycle with cold water. Use mild detergent. Avoid harsh chemicals like bleach. Air dry or tumble dry on a low setting.

Is digital printing expensive process?

arrow_drop_downDigital printing can be more expensive than traditional printing methods initially due to the cost of specialized equipment and inks. However, it offers advantages like shorter production times, customization options, and reduced waste, which can offset costs.

Which ink is used in digital printing?

arrow_drop_downIn digital fabric printing, specialized textile inks are used. These inks are formulated to adhere to fabric fibers and withstand washing and wear, ensuring vibrant and durable prints on textiles.

How digital printing is done on fabric?

arrow_drop_downIn digital fabric printing, designs are directly printed onto fabric using inkjet printers equipped with specialized textile inks. The process involves digitally transferring the design onto the fabric with precision and detail.

How long do digital prints last?

arrow_drop_downThe longevity of digital prints on fabric depends on factors such as the quality of materials, printing process, and care. With proper care and maintenance, digital prints can last for years without significant fading or deterioration.

What types of fabrics can be used for digital printing?

arrow_drop_downWe primarily work with natural fabrics like cotton, silk, and linen. If you have a specific fabric in mind, please contact us to confirm its compatibility with digital printing.

More Stories

naturally dyed block printing

hand block printing

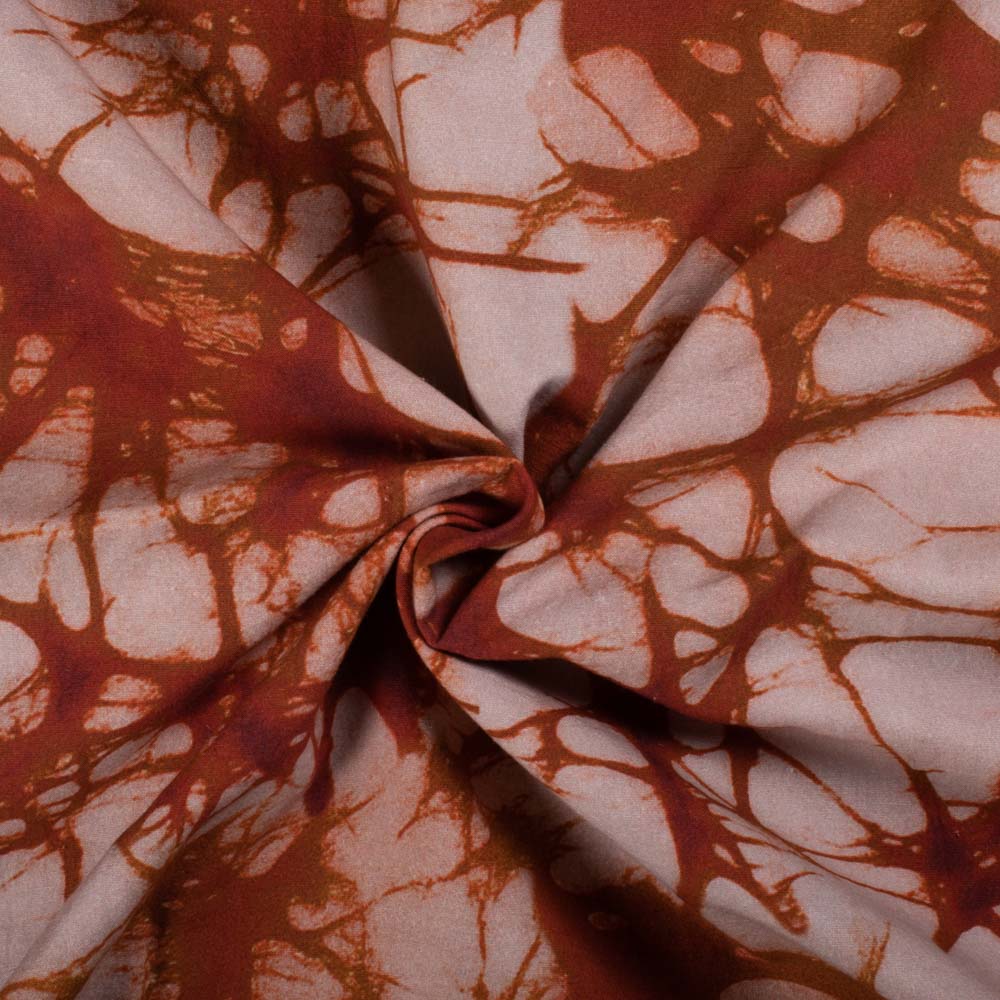

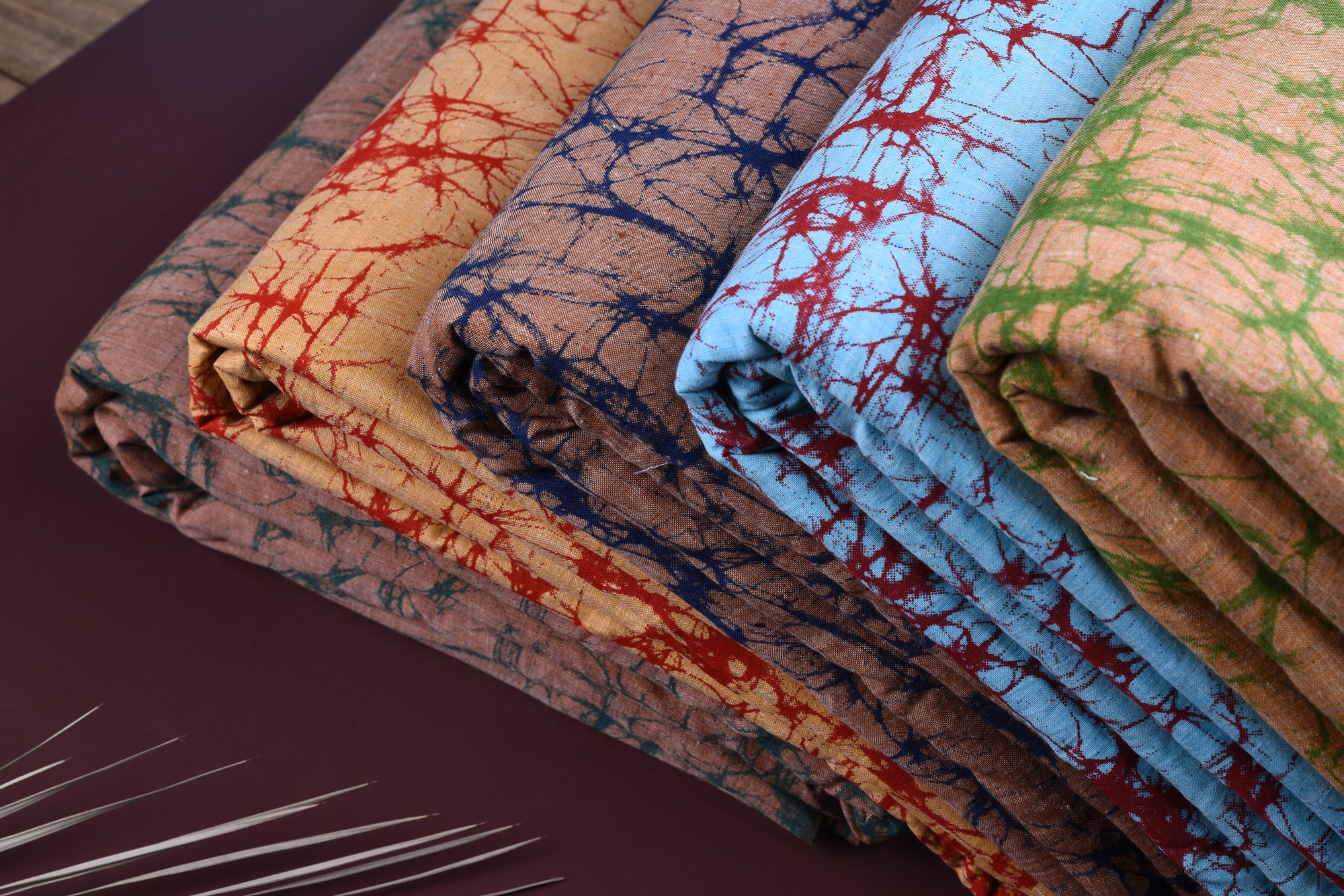

handprinted batik

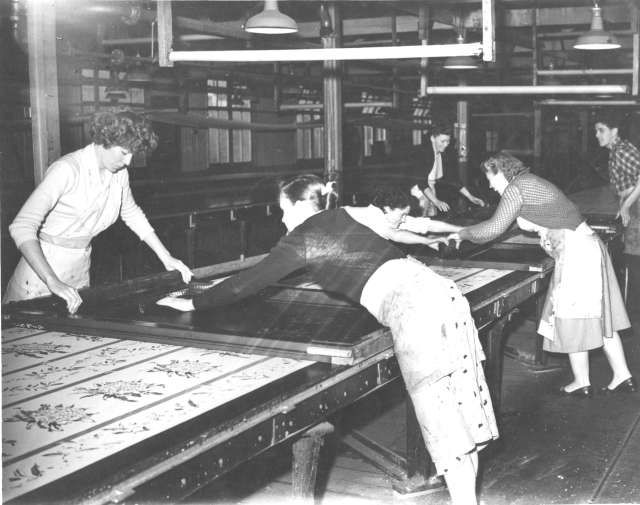

screen printing

madhubani wall art

patachittra wall art