Screen Printing on Natural Fabrics: What Experience Teaches That Manuals Don’t

Screen printing is one of the most familiar textile techniques in design studios and production floors alike. Most designers understand the mechanics, the inks and the visual possibilities. Yet, when screen printing meets natural fabrics, especially handloom and sustainable materials, subtle but critical factors are often overlooked. These gaps don’t usually show up in the first sample but surface later, during scaling, washing or long-term wear.

This isn’t about relearning screen printing basics. It’s about understanding the quiet fabric-led realities that shape outcomes more than the artwork itself.

Screen Printing Is Never Fabric-Neutral

One of the most common assumptions is that screen printing behaves consistently across fabrics. In reality, natural fabrics respond to ink based on fiber structure, absorbency, yarn irregularity and surface tension. Cotton, silk, bamboo blends and textured weaves all interact differently with the same screen, ink, and pressure.

Designers often perfect artwork digitally and expect the fabric to simply “receive” it. Natural fabrics don’t work that way. They participate in the process. Ignoring this interaction leads to blurred edges, uneven coverage or prints that age poorly after washing. Understanding fabric behavior is not a production concern. It’s a design responsibility.

Khadi Cotton Fabric and the Myth of Precision

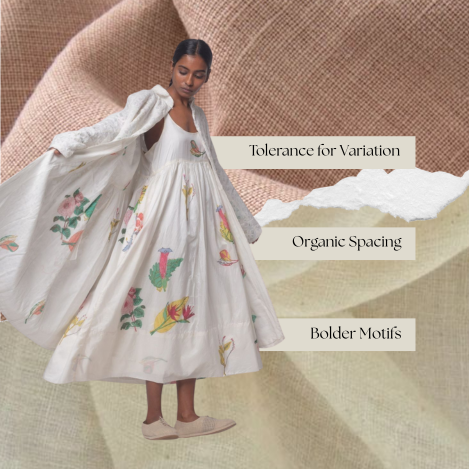

Khadi cotton fabric is valued for its handspun character, breathability and cultural depth. What designers often miss is how its irregular yarn thickness and slight surface variations affect screen printing results.

Perfect symmetry, ultra-fine detailing and tight registration can be difficult to achieve consistently on khadi. Trying to force precision usually results in higher rejection rates or visual compromise. Designers who work successfully with khadi adapt their artwork: bolder motifs, organic spacing and tolerance for variation. The fabric rewards designs that respect its rhythm rather than resist it.

Silk Requires Restraint More Than Saturation

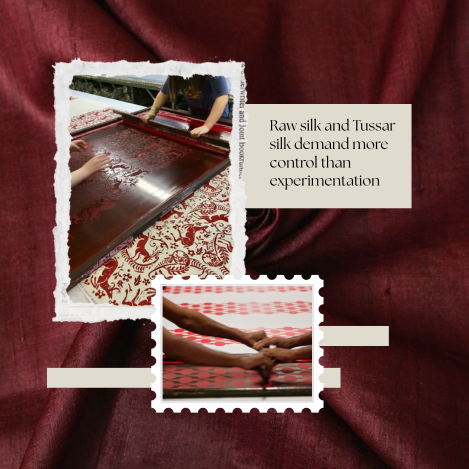

Silk is frequently approached as a luxury canvas that can “handle anything.” In practice, raw silk and tussar silk demand more control than experimentation.

Raw silk’s uneven filament structure influences ink spread, making heavy ink application risky. Over-saturation can stiffen the fabric and dull its natural sheen. Tussar silk, with its characteristic slubs and texture, poses another challenge, fine lines and intricate details often break visually once printed. Designs that work best on tussar silk tend to emphasize texture, negative space and natural movement rather than sharp precision.

Designers often focus on color payoff, but longevity, hand feel and drape matter more on silk. These qualities are easy to compromise and hard to recover.

Sustainability Doesn’t Cancel Technical Discipline

Bamboo linen fabric and other plant-based textiles are increasingly popular for their sustainability credentials. What’s often missed is that eco-friendly fibers still demand strict technical handling during screen printing.

Bamboo blends, for instance, retain moisture differently than cotton. Improper curing can lead to prints that appear fine initially but crack or fade prematurely. Similarly, banana fiber and other alternative textiles amplify mistakes rather than hide them. Sustainability doesn’t make a fabric forgiving, it makes the margin for error smaller.

Designers who work with these materials need to think beyond visual impact and consider how ink choice, curing time and print sequencing affect durability and waste.

Where Design Thinking Often Stops Too Early

A common blind spot in screen printing workflows is timing. Decisions about whether printing happens before or after cutting, how fabric tension changes across batches or how a design behaves at scale are often left to production teams.

Natural fabrics shift slightly between lots, humidity levels and handling stages. A design that works beautifully in a small run may struggle when scaled unless these variables are anticipated early. This is particularly true when printing on textured or woven surfaces like jacquard, where raised patterns can distort flat prints if not planned for.

Experienced designers extend their thinking beyond the artwork file. They design with process, sequence, and material behavior in mind.

The Fabric Always Has the Final Say

Screen printing on natural fabrics is not just a technique but a negotiation between design intent and material truth. Khadi cotton fabric, raw silk, tussar silk, bamboo linen fabric and textured weaves all bring strengths, but they also set boundaries.

Designers who miss these nuances don’t fail immediately. The issues appear later: in wear, in wash, in scale and in sustainability outcomes. Those who understand fabric behavior early create work that not only looks right but lasts, performs, and aligns with the values these materials represent.

In natural textiles, the fabric is never passive. The sooner design decisions acknowledge that, the stronger the result.

most asked questions

Why does screen printing behave differently on natural fabrics compared to synthetic ones?

arrow_drop_downNatural fabrics vary in fiber structure, absorbency, and surface texture. These variables affect how ink spreads, cures, and ages over time, making screen printing outcomes less predictable but more material-driven than on uniform synthetic fabrics.

Is screen printing suitable for textured fabrics like khadi cotton fabric or tussar silk?

arrow_drop_downYes, but success depends on adapting the design. Textured fabrics soften edges and disrupt fine detailing, so bolder motifs, open spacing, and an acceptance of variation typically produce better and more durable results.

Why do prints sometimes fade or crack on sustainable fabrics after washing?

arrow_drop_downThis usually results from mismatched ink systems, improper curing, or moisture retention in the fabric. Sustainable and plant-based fabrics amplify technical errors, making precise process control essential for long-term print quality.

At what stage should screen printing be planned when working with natural textiles?

arrow_drop_downScreen printing should be considered during the design and sampling phase, not treated as a finishing step. Fabric tension, batch variation, and cutting sequence all influence final results, especially at production scale

More Blogs

from sericulture to spun yarn: a deep dive into the artisanal raw silk production process

raw silk vs. mulberry silk: a technical comparison for textile designers

the ultimate sourcing guide to raw silk fabric: properties, weights, and creative uses

handspun khadi vs. mill-made cotton: why khadi online shopping offers more value

the comprehensive b2b buyer’s guide to tussar silk wholesale sourcing

buying authentic khadi online: 7 quality tests for b2b sourcing