Screen Printing vs Digital Printing: The Ultimate Guide for Sustainable Textile Sourcing

In sustainable fashion, how you apply color matters as much as the fiber itself. For B2B buyers and fashion entrepreneurs, choosing between screen printing and digital printing is not just a technical call. It shapes your brand aesthetic, production economics, and environmental impact.

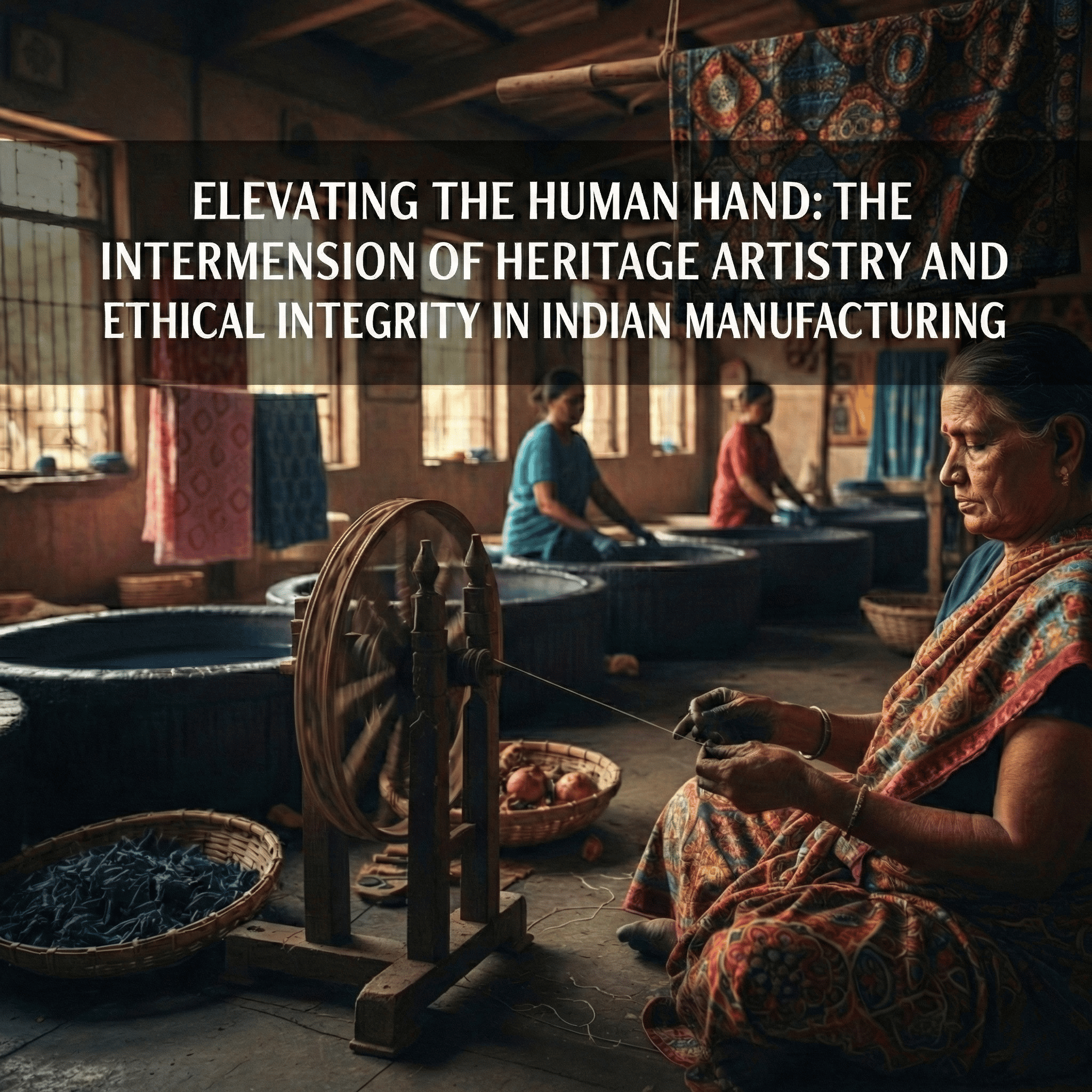

At Anuprerna, we work at the intersection of handwoven textiles and modern manufacturing. We understand that whether you are sourcing wholesale fabric printing for a global collection or a niche artisan line, the nuances of the printing process matter. Screen printing brings depth, texture and heritage appeal. Digital printing unlocks precision, speed and design flexibility.

This guide breaks down the mechanics, cost structures, and sustainability trade-offs of both methods so your next sourcing decision is aligned with your brand strategy, not just your artwork.

The Art and Science of Screen Printing

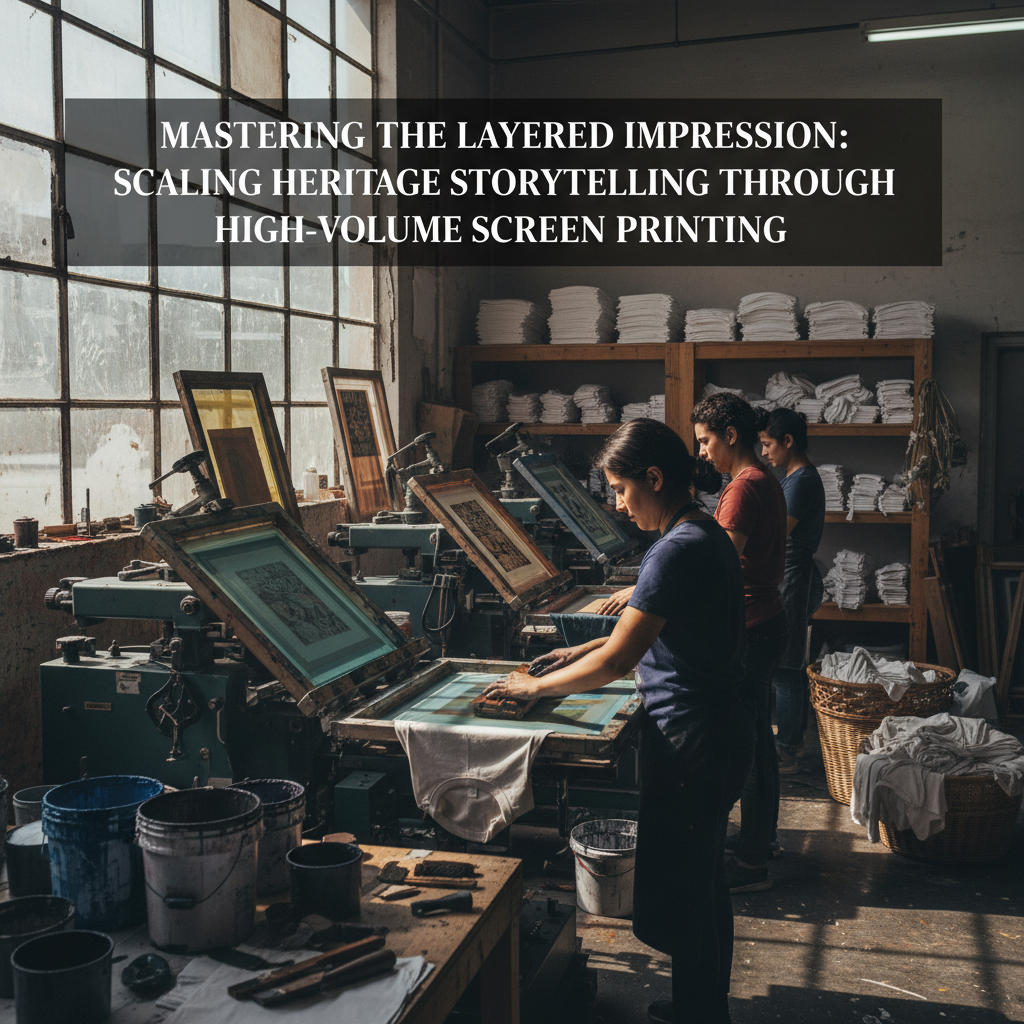

Screen printing is a foundational technique in the Indian textile industry, celebrated for its durability and the depth of color it achieves. The process involves creating a stencil (or "screen") for each color in a design. Ink is then pushed through the mesh screen onto the fabric using a squeegee.

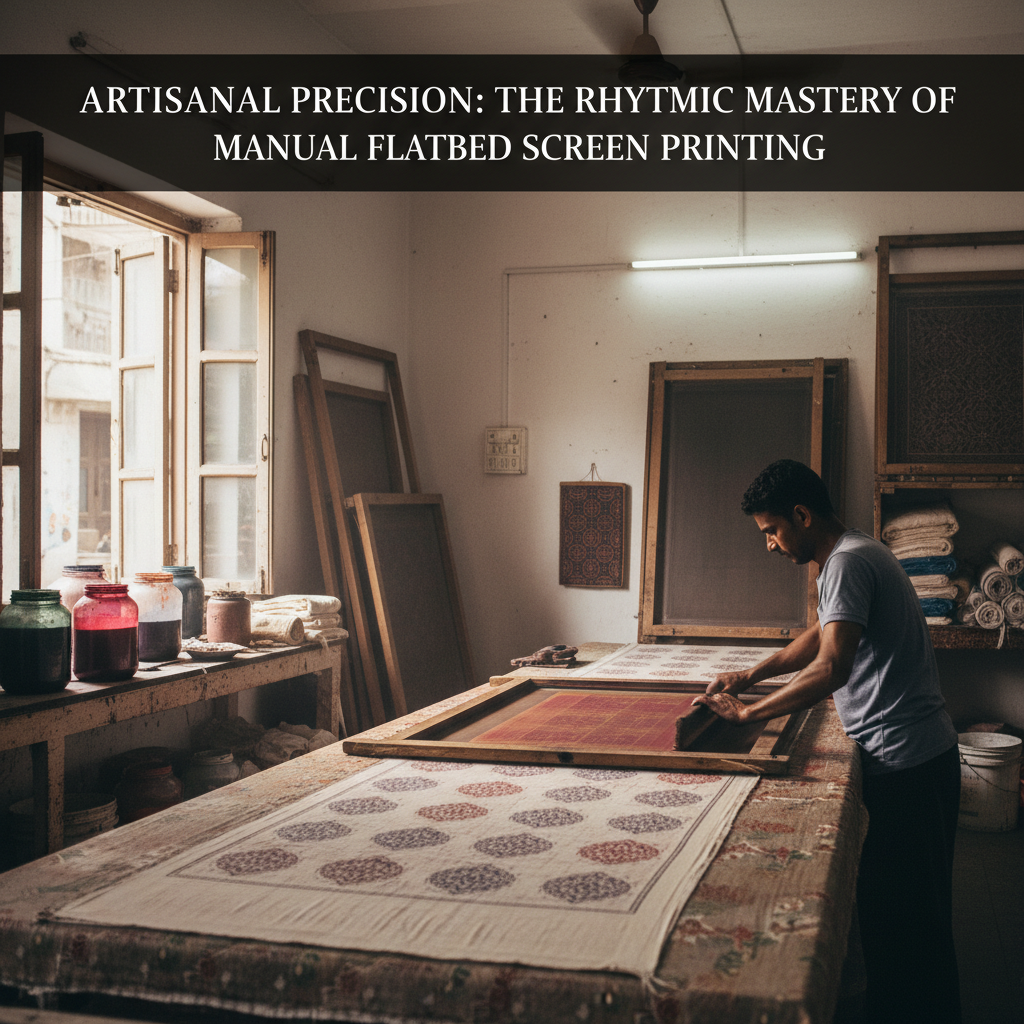

The Process of Manual and Flatbed Screen Printing

In the context of artisanal manufacturing, screen printing often takes two forms: hand-screen printing and flatbed machine printing. At Anuprerna, we emphasize the human element. Hand-screen printing requires immense precision; two artisans move a large screen across long tables of fabric, meticulously aligning each "repeat" of the pattern.

This method is particularly effective on natural fibers like Khadi and Silk. Because the ink sits on top of the fibers or penetrates deeply depending on the paste used, the result is a vibrant, long-lasting finish. To learn more about the technical nuances, explore our insights on screen printing on natural fabrics.

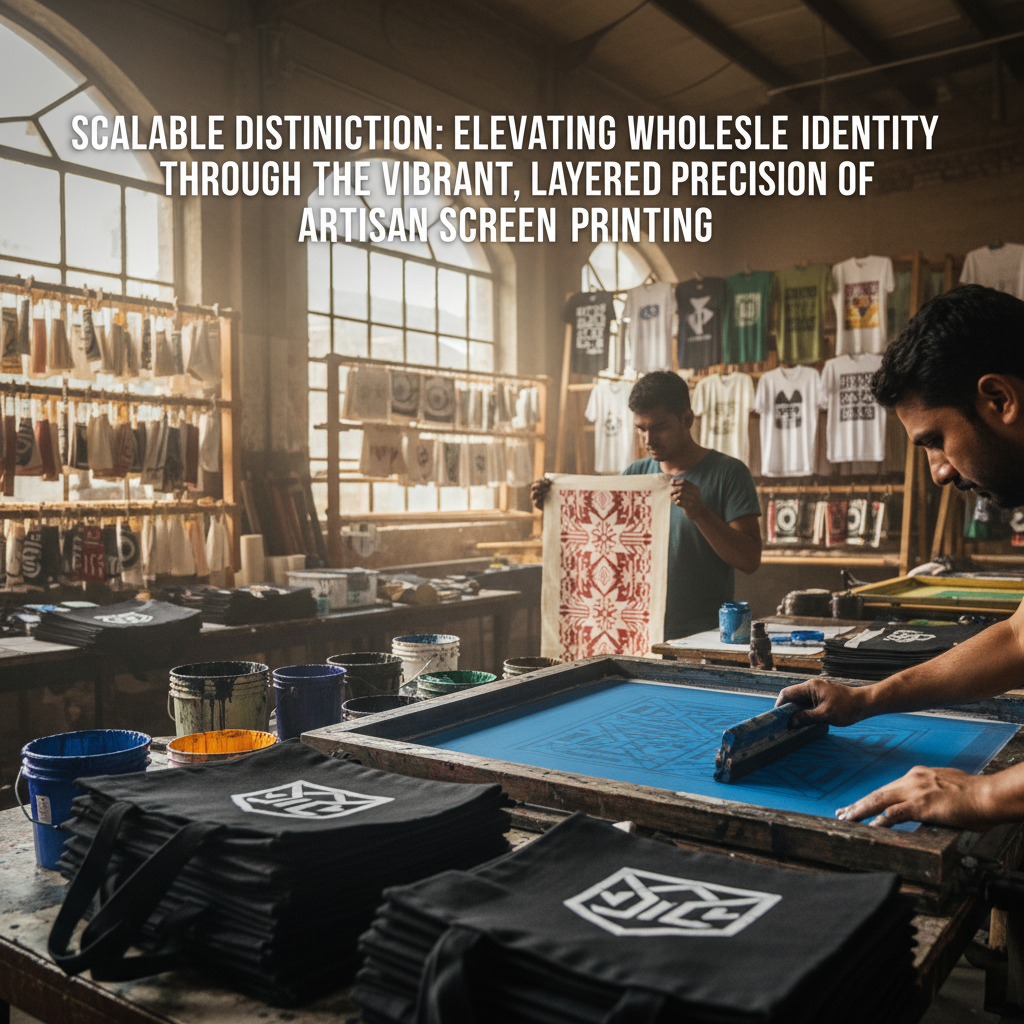

Why B2B Brands Choose Screen Printing

- Vibrancy and Opacity: Screen printing allows for thicker ink application, which results in exceptionally bright colors, even on darker fabrics.

- Specialty Inks: If your design requires metallic finishes, puff inks, or specific pantone matching in large batches, screen printing is the go-to.

- Scalability: While the initial setup (creating screens) is costly and time-consuming, the cost per meter drops significantly as the volume increases, making it ideal for wholesale fabric printing.

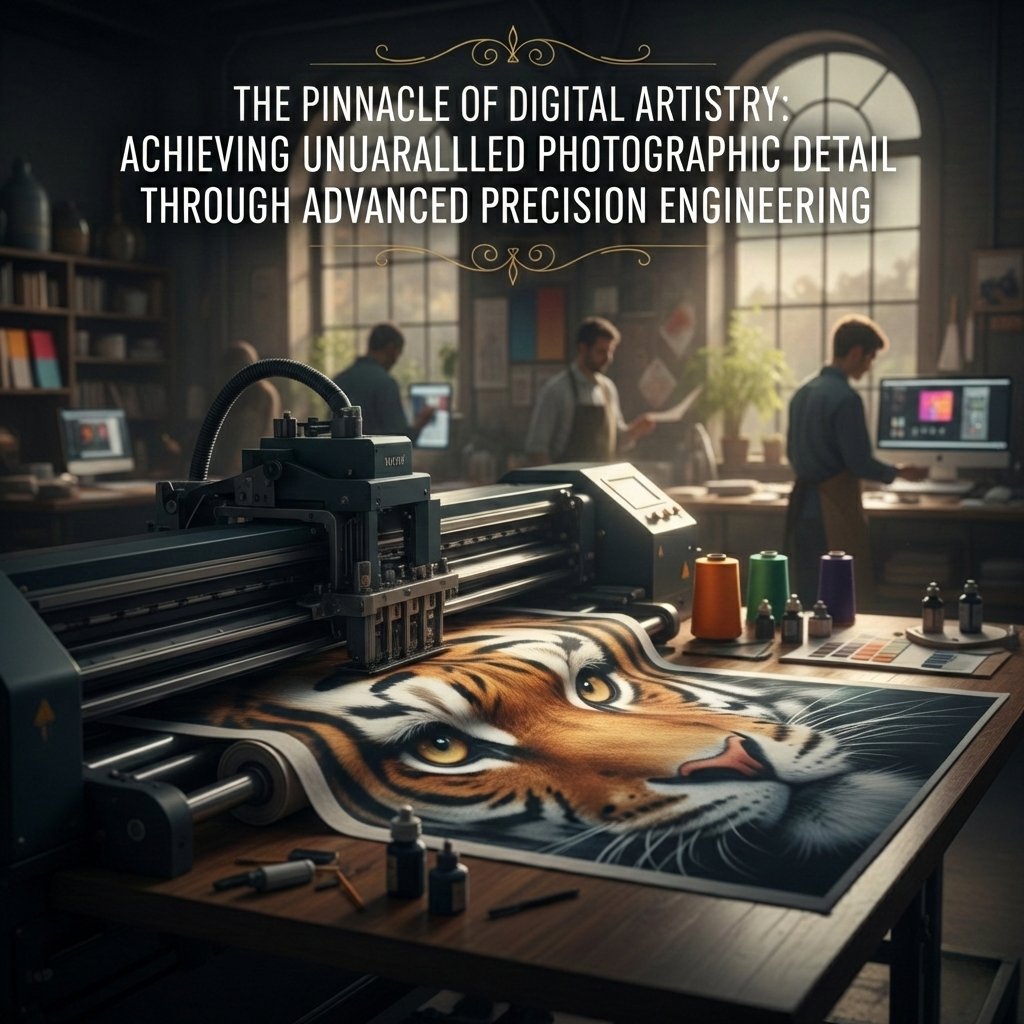

Digital Printing: The Modern Frontier

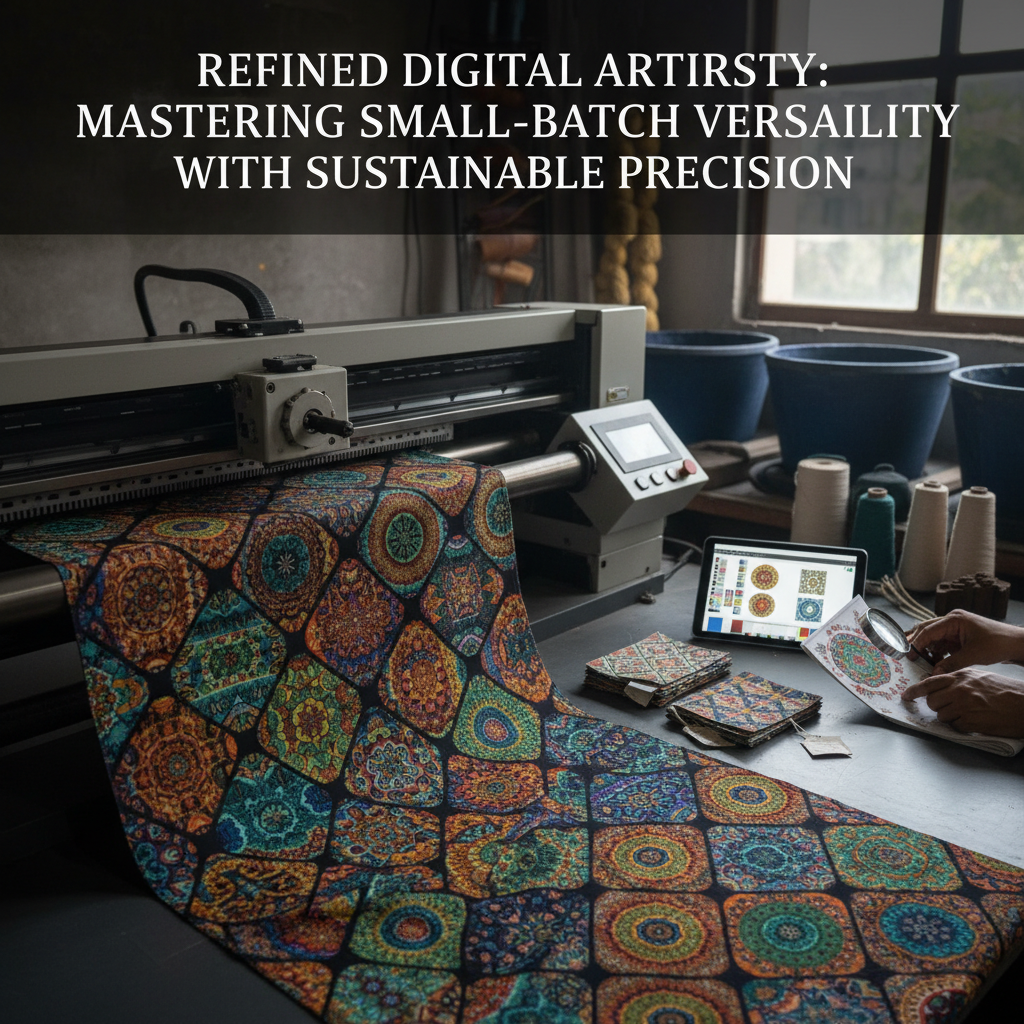

Digital printing, often referred to as Direct-to-Garment (DTG) or Direct-to-Fabric printing, works much like your office inkjet printer but on a massive scale with specialized textile inks.

Precision and Complexity

Digital printing excels at reproducing photographic detail and seamless color gradients. With no screens to prepare, the setup is fully digital, making it ideal for intricate, multi-colored designs that would be impractical or too costly with screen printing.

Sustainability Considerations

Digital printing typically uses less water since there are no screens to wash between colors, and ink is applied only where needed. That said, sustainability depends on ink chemistry. We recommend using GOTS-certified inks to ensure the environmental benefits extend beyond just water savings.

You can browse our range of digitally printed and screen-printed fabrics to see the visual difference in detail and texture.

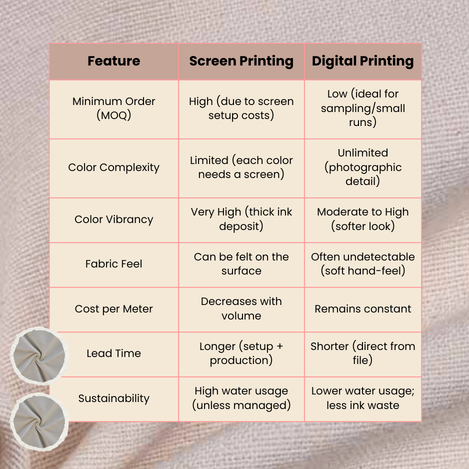

Screen Printing vs Digital Printing: A Head-to-Head Comparison

Strategic Sourcing: Which One Fits Your Business Model?

When to Choose Screen Printing for Wholesale

If you are an established brand looking to produce 500+ meters of a signature floral print on Calico fabric, screen printing is your best ally. The durability of the print ensures that the garments will withstand repeated washing, which is vital for maintaining brand reputation. Furthermore, the cultural authenticity of hand-screen printing adds a storytelling element to your marketing, highlighting the "human touch" in your supply chain.

When to Choose Digital Printing

For emerging designers or boutique brands focusing on "slow fashion" with limited drops, digital printing offers the flexibility to experiment without a heavy upfront investment. It allows for "Print on Demand" models that significantly reduce deadstock, one of the fashion industry's biggest sustainability hurdles.

Sustainability and Ethical Manufacturing in India

At Anuprerna, our focus is on more than just the output; it’s about the impact. India has a rich history of textile printing, but the shift toward mass production has often come at an environmental cost.

Whether we are facilitating screen printing or digital printing, we adhere to strict ethical standards:

- Water Management: We support units that implement water treatment and recycling to mitigate the impact of screen washing.

- Artisan Support: Screen printing is a skill-intensive craft. By choosing this method, brands help sustain the livelihoods of artisan communities in East India who have passed down these techniques through generations.

- Natural Fibers: We specialize in printing on handwoven cotton, silk, and linen. These biodegradable bases ensure that even as we use modern printing technology, the core of the product remains rooted in nature.

When you engage in smart sourcing for your brand, you are choosing a partner that values the longevity of both the craft and the planet.

Screen vs Digital Printing: Choosing the Right Path for Your Brand

The choice between screen printing vs digital printing is not a matter of which is "better," but which is "better for your specific needs." Screen printing offers unmatched vibrancy, cost-efficiency at scale, and a rich connection to traditional craftsmanship. Digital printing offers the precision, flexibility and low-waste benefits required for modern, agile fashion brands.

As a B2B partner, Anuprerna is dedicated to helping you navigate these choices. We provide the expertise to ensure that your designs are translated onto fabric with the highest quality, whether through the rhythmic stroke of an artisan's squeegee or the high-tech precision of a digital nozzle.

Ready to elevate your collection with sustainable printed fabrics? Explore our Fabric Collections or contact our sourcing team today to discuss your custom printing requirements.

most asked questions

Is screen printing more durable than digital printing?

arrow_drop_downGenerally, yes. Screen printing uses thicker inks and a heat-curing process that bonds the ink deeply with the fabric fibers. This makes it highly resistant to fading and cracking over time. Digital printing has improved significantly, but on certain fabrics, it may show signs of wear sooner than screen-printed designs, especially if not cared for properly.

Which method is better for small-batch sustainable brands?

arrow_drop_downDigital printing is typically better for small batches. Since there are no physical screens to create, the setup cost is minimal, allowing brands to print small runs (even 10-20 meters) without a high price penalty. This prevents overproduction and reduces textile waste, aligning with sustainable "slow fashion" principles.

Can I use screen printing for complex, multi-colored designs?

arrow_drop_downYou can, but it becomes expensive and technically difficult. Each color in screen printing requires its own screen and a separate pass of ink. If your design has 12 different colors, you need 12 screens. For designs with gradients or photographic elements, digital printing is much more efficient and produces a better result.

Does digital printing work on all types of fabric?

arrow_drop_downDigital printing is most effective on natural fibers like cotton, silk, and linen when using reactive or acid inks. However, the fabric must be pre-treated to "accept" the ink. While it works beautifully on our handwoven fabrics, the results can vary depending on the weave density. Screen printing is often more versatile across a wider range of fabric textures.

How does the cost of wholesale fabric printing differ between these two?

arrow_drop_downFor wholesale fabric printing, screen printing follows an "economies of scale" model—the more you print, the cheaper it gets per meter. Digital printing has a relatively flat pricing structure; the cost for the 100th meter is usually the same as the 1st meter. Therefore, for large bulk orders, screen printing is almost always more cost-effective.

More Blogs

a handloom style guide: choosing the right weaves for your body type

mastering screen printing on khadi: challenges, best practices, and sustainable solutions

navigating the logistics of fabrics wholesale: a guide to indian bulk textile export

from sericulture to spun yarn: a deep dive into the artisanal raw silk production process

khaadi online shopping guide: khaadi vs organic linen for sustainable summer fashion

the art of hand screen printing: a step-by-step guide to artisanal fabric printing