Understanding Mulberry Silk Quality: What Designers Often Miss and Why It Matters

Mulberry silk fabric looks perfect at first glance. Its real test comes later.

It is synonymous with luxury, fluid drape and premium pricing, and designers know how beautifully it photographs and feels. But silk is a delicate, responsive fabric. Its true quality reveals itself through dyeing, wear, washing and care, not at the sampling stage.

When problems appear, they are often blamed on other factors. More often, they come from a misunderstanding of silk fabric material and how quality choices affect real-world performance.

This article explores the less visible aspects of mulberry silk fabric quality that determine whether a garment ages gracefully or disappoints over time.

Why Mulberry Silk Quality Is More Than Look and Feel

Mulberry silk is usually judged by sheen, softness, weight and fall. GSM and price often seal the decision. These cues are convenient, but they reveal only part of the story.

Silk fabric is unforgiving. Small compromises in processing or structure show up over time as uneven dyeing, seam distortion, fading, or loss of strength. Two rolls of mulberry silk fabric can look identical on day one and perform very differently after months of use if not taken care of or used extensively.

The issue is not designer judgement. It is how silk quality is presented. Most suppliers sell silk as a surface experience. Designers need to evaluate it as a performance material.

The Structural Core of Silk: Filament Length, Degumming, and Yarn Twist

The true quality of mulberry silk begins at the filament level. Mulberry silk is prized because it is made from long, continuous filaments reeled from Bombyx mori cocoons. However, not all silk maintains that continuity through processing.

- Filament length consistency shapes drape, surface smoothness and longevity. Silks made from shorter or broken filaments tend to fuzz, pill and lose sheen with wear, especially in scarves and garments worn close to the skin. Longer filament silk retains its finish and structure far better over time.

- Degumming is another critical but under-discussed factor. Silk naturally contains sericin, a protein that binds the filaments. Removing sericin makes silk soft and lustrous, but degumming is not an all-or-nothing process.

Over-degummed silk feels soft but weakens quickly. Under-degummed silk stays strong but feels stiff and dyes unevenly. Two silk fabric materials with the same GSM can perform very differently based on degumming alone.

Yarn twist further defines performance.

- Low twist: high sheen, extreme softness, lower abrasion resistance; best for occasion wear.

- Higher twist: slightly matte, stronger, better shape retention; better for daily wear and structured silhouettes.

Yarn ply also matters. Multi-ply silk yarns add strength and abrasion resistance without significantly affecting drape, especially in garments designed for repeated wear.

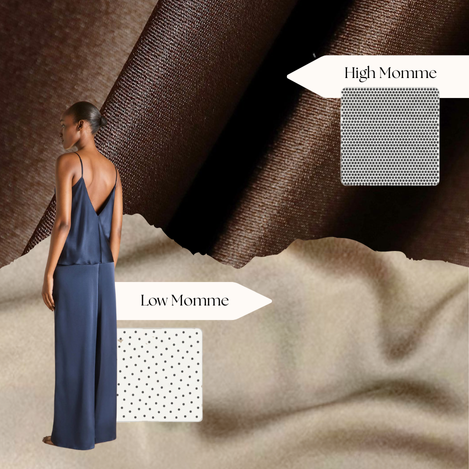

Density and Stability: Why Momme and Weave Structure Matter

Relying on GSM alone is a common sourcing mistake. GSM measures weight, not durability. In silk, momme matters more because it reflects filament density, strength and lifespan. Two mulberry silk fabrics with similar GSM can perform very differently if their momme differs. A 16 momme silk will hold shape and resist wear far better than a lower-density alternative.

Weave tension is equally critical. Silk exaggerates structural flaws, which later appear as puckering, twisted seams or panel distortion, often after washing. Bias-cut garments, panelled silhouettes, and printed silk fabric are especially sensitive. At this level, weave stability is not optional.

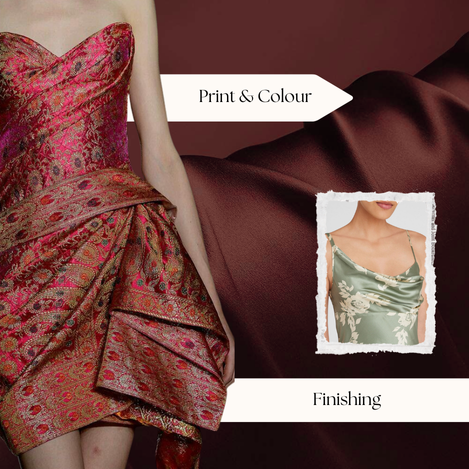

Color, Finish and Performance Over Time

Silk takes dye easily, but bright color on day one does not ensure longevity. Dye penetration depth determines how well color holds with wear and washing. Surface-dyed silk fades faster, especially in dark shades, while deeper penetration improves colorfastness and stability.

Printed silk fabric is even more sensitive. Print performance depends on the base silk’s absorbency, degumming balance and weave stability. Weak foundations lead to fading, cracking, or distortion over time.

All silk eventually experiences fatigue. Repeated wear reveals flaws in filament quality, degumming and yarn twist. True silk quality shows up after use, not at the first fitting.

Designing With Silk Intentionally: Matching Quality to Use Case

Silk should be treated as a system, not a single specification. Filament quality, degumming, yarn twist, momme, weave stability and dye process must align with the end use. Lightweight applications need softness, while regular-wear garments demand higher density and structural balance. This also reframes conversations around mulberry silk price. Cost differences reflect processing choices that affect performance, longevity and waste. Well-specified silk is not just a luxury. It is one of the more responsible sustainable fabrics when designed to last.

Designers who ask better sourcing questions design better products. Silk failures are rarely aesthetic. They come from mismatches between material quality and real-world use.

At Anuprerna, we believe silk deserves that level of respect. Not as a surface-level luxury, but as a material whose integrity carries the story of craft, process and thoughtful design from cocoon to cloth.

most asked questions

Is mulberry silk fabric suitable for everyday wear?

arrow_drop_downYes, mulberry silk fabric can be worn daily when the weave and finish are chosen correctly. Well-made mulberry silk holds up well to regular use, offering comfort, breathability, and durability without feeling delicate or high-maintenance.

How is mulberry silk fabric different from other silk fabrics?

arrow_drop_downMulberry silk fabric is made from long, continuous filaments, which results in a smoother surface, better drape, and more consistent quality. Compared to other silk fabrics, it tends to feel softer, look more uniform, and perform more predictably in garment construction.

Does printed silk fabric made from mulberry silk last well?

arrow_drop_downYes. Printed silk fabric produced from quality mulberry silk retains colour clarity and softness when dyed and finished properly. The fabric absorbs colour evenly, which helps prints age gracefully without becoming stiff or patchy over time.

Why does mulberry silk price vary so much?

arrow_drop_downMulberry silk price depends on factors like filament quality, weave type, finishing process, and sourcing practices. Higher-quality silk may cost more upfront, but it offers better longevity, consistency, and overall value in finished products.

More Blogs

raw silk vs. mulberry silk: a technical comparison for textile designers

the ultimate sourcing guide to raw silk fabric: properties, weights, and creative uses

handspun khadi vs. mill-made cotton: why khadi online shopping offers more value

the comprehensive b2b buyer’s guide to tussar silk wholesale sourcing

buying authentic khadi online: 7 quality tests for b2b sourcing

screen printing on natural fabrics: what experience teaches that manuals don’t