HANDWOVEN MERINO WOOL

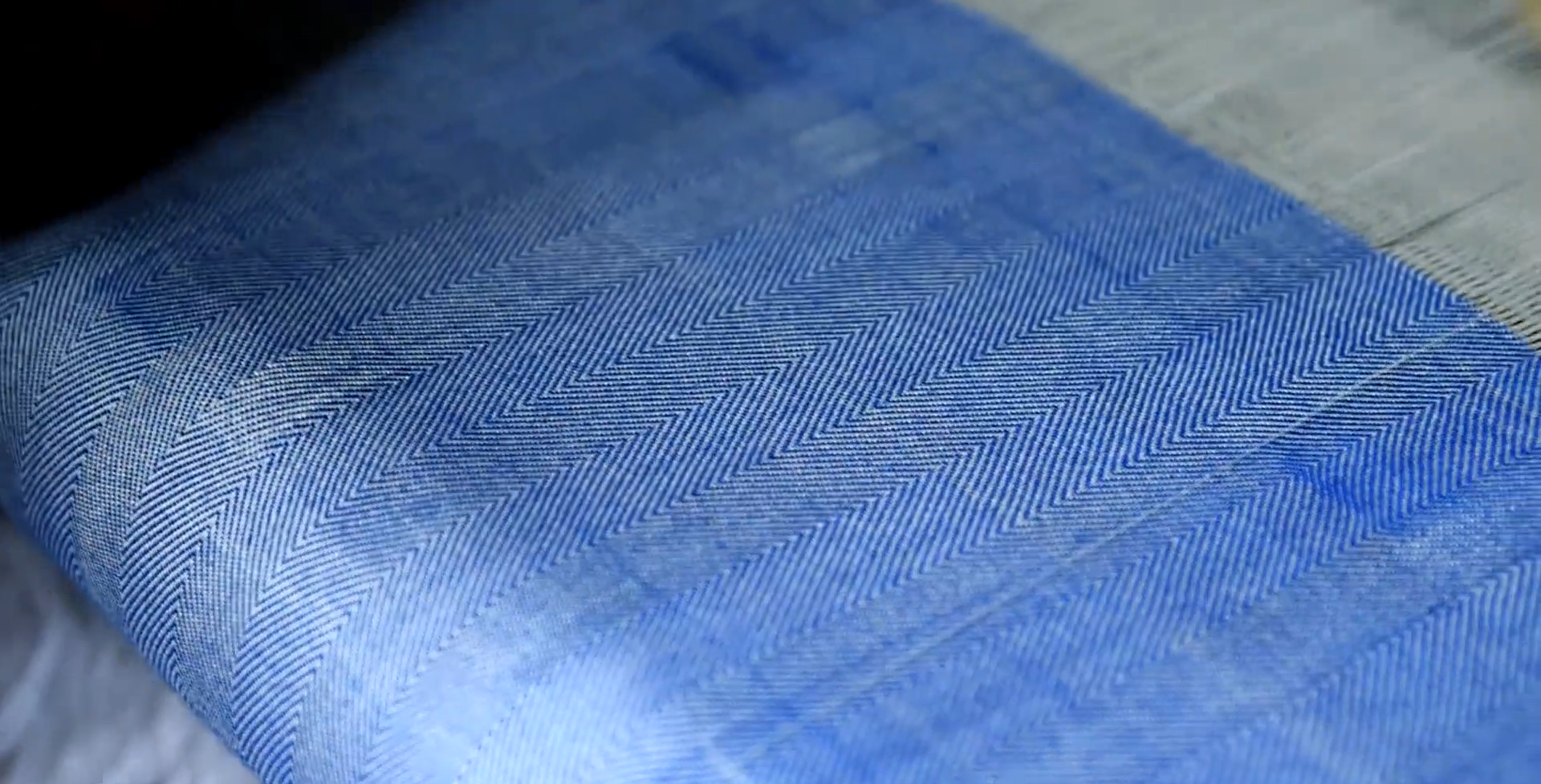

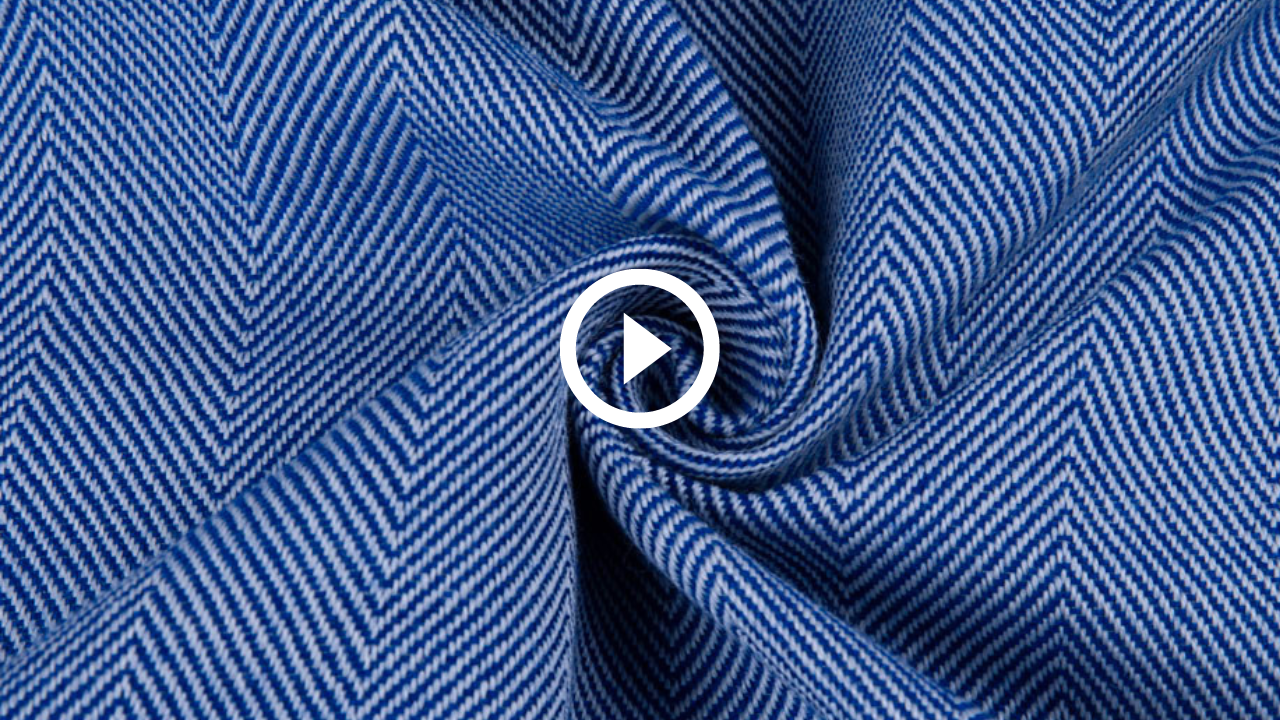

Our Handwoven Organic Merino Woollen Fabrics Are Made From Responsibly Sourced Woolmark & RWS Certified Organic Wool Yarn & Crafted By Our Artisans Using Handlooms. Merino Wool Is Highly Regarded for its Exquisite Smoothness And Luxurious Feel.

HANDWOVEN MERINO WOOL PROCESS

INTRODUCTION

Merino wool is a luxurious and highly versatile material derived from the coats of Merino sheep. Known for their fine, shiny, and smooth fleece, these sheep produce wool that is in demand for various applications, particularly in the production of high-quality sweaters. One of the key reasons for Merino wool's popularity is its exceptional warmth-to-weight ratio, which sets it apart from other types of wool, including cashmere.

Its unique properties make it a versatile and high-performance material for both outdoor and everyday wear, providing comfort and style in a wide range of climates and activities.

HISTORY

From ancient times, sheep have been utilized for their wool to make clothing. However, recent findings in Iran's archaeological records indicate that the deliberate breeding and selection for woolly sheep began around 6000 BC. The earliest discovered woven wool garments date back to two to three thousand years after this period. In Europe, woolly sheep were introduced in the early 4th millennium BC. The oldest known wool textile in Europe dates to approximately 1500 BC.

PROCESSING OF WOOL FIBRE INTO WOOLEN TEXTILE

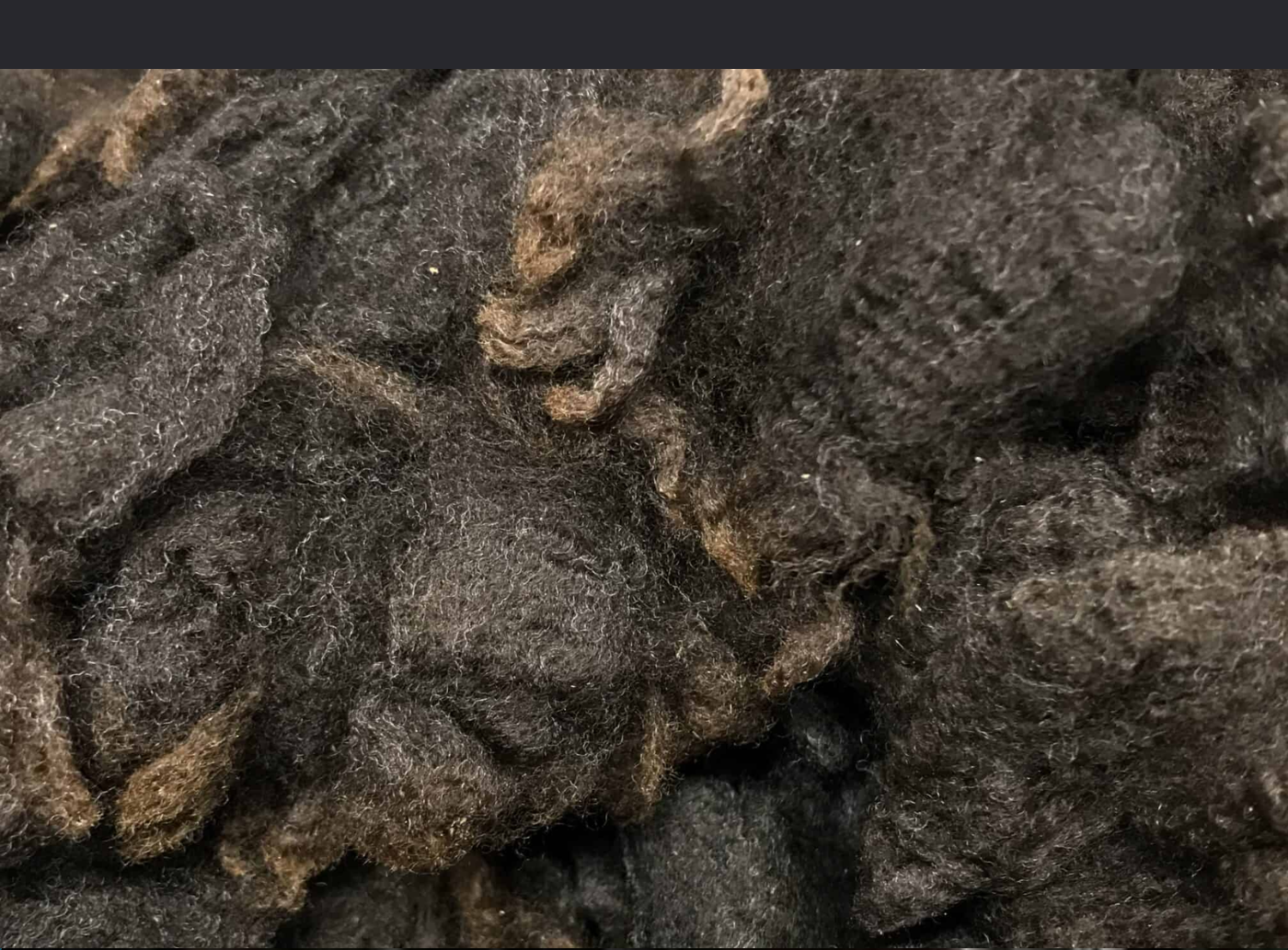

STEP 1: FLEECE PROCESSING

This procedure involves shearing merino sheep's skin to separate the fur. Subsequently, the fur is cleansed and dried to eliminate any accumulated dirt or debris.

STEP 2: SCOURING

The process involves washing and drying the wool in a series of tumbling machines. The use of water and mechanical agitation removes dirt, dust, soil, and other impurities from the wool.

STEP 3: GRADING & SORTING

The grading of fibers is determined by their type, length, quality, flexibility, and durability. The process starts by separating the fibers based on their texture and appearance.

STEP 4: CARDING

Carding aligns the fibers in a parallel direction and eliminates some dirt particles by straightening the fibers.

STEP 5: GILLING & COMBING

Gilling is the method used to eliminate shorter fibers from wool while Combing involves getting rid of longer fibers from wool.

STEP 6: ROVING & SPINNING

In this particular kind of untwisted fiber known as "top," the wool fibers are gently brushed before being pulled into a continuous strand called a roving. The process of spinning requires the roving to be drawn out and made thinner through twisting, which enhances its strength.

STEP 7: DYEING

Yarn is dyed in the desired hue using Azo-free or natural dyes.

STEP 8: WINDING & WARPING

Dyed wool yarns are wrapped around bobbins. The warp yarn is then moved from the bobbins to the warping drum and later transferred to the weaver's beam.

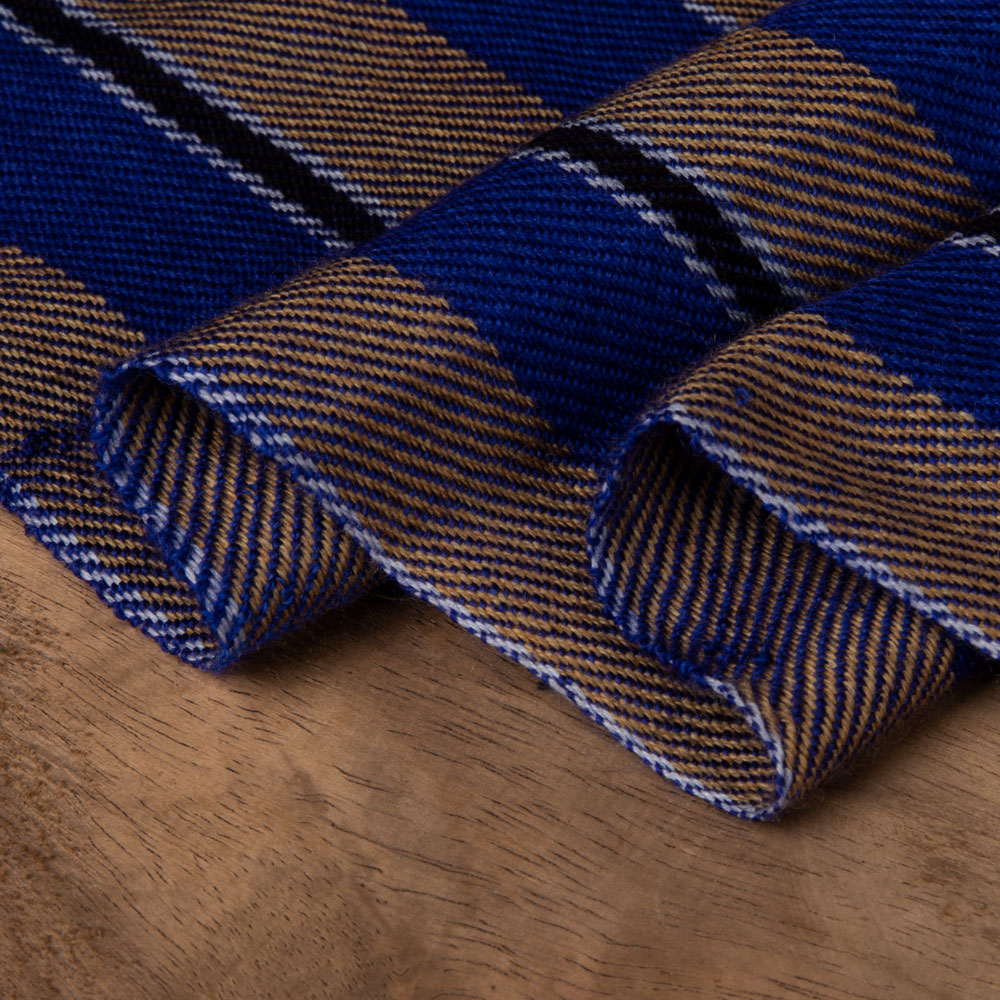

STEP 9: DENTING & WEAVING

Once the loom is prepared, the process of weaving with wool yarn commences. The yarn is pulled from the weavers' beam and threaded through the heald eye of the heald wire. Subsequently, the yarn is further drawn through the reed dents while being placed.

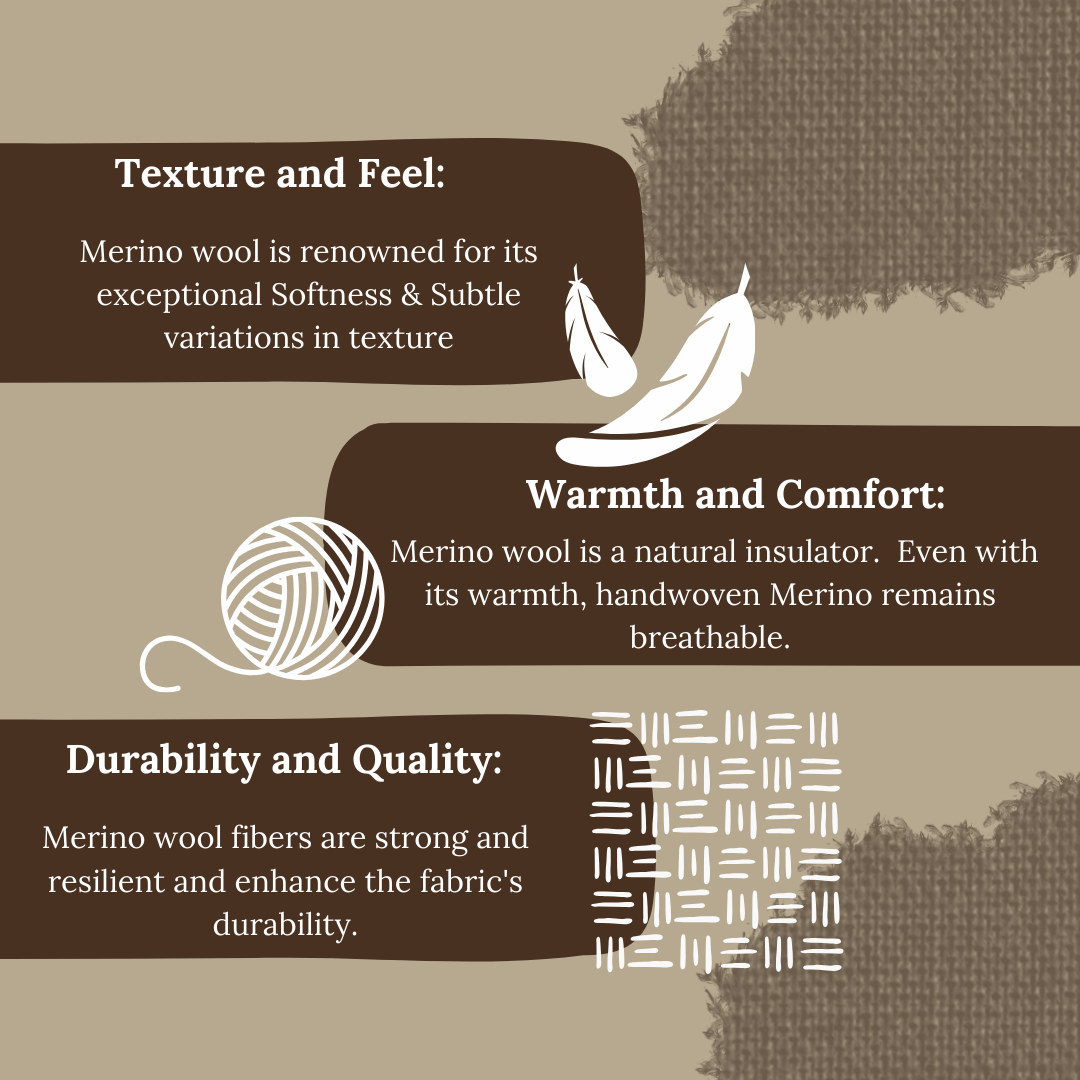

CHARACTERISTICS :

frequently asked questions

What are the advantages of using handwoven merino wool?

arrow_drop_downHandwoven merino wool presents various benefits: it is incredibly gentle and cozy on the skin, it offers exceptional insulation and warmth, which makes it perfect for chilly conditions. Moreover, merino wool efficiently absorbs moisture and regulates body temperature. Additionally, high-grade merino wool is known for its durability and long-lasting nature.

What are the common applications of handwoven merino wool fabric?

arrow_drop_downHandwoven merino wool fabric is used in a wide range of applications, including clothing, accessories, and home textiles.

Is handwoven merino wool suitable for all seasons?

arrow_drop_downHandwoven merino wool is versatile and can be suitable for various seasons. It offers warmth in colder months and remains breathable in warmer weather, making it a year-round option.

Does handwoven merino wool require special care compared to other wool fabrics?

arrow_drop_downMerino wool, including handwoven varieties, typically requires gentle care. It is best to hand wash in cold water using a mild detergent and to avoid wringing or twisting the fabric. Dry it flat to maintain its shape and softness.

Can handwoven merino wool fabrics be customized with specific designs or patterns?

arrow_drop_downIndeed, handweaving craftsmen possess the expertise to produce custom designs and intricate patterns on merino wool fabrics through their artisanal skills. This capability enables the creation of exclusive and personalized pieces. Clients have the opportunity to collaborate with these craftsmen, sharing their preferences and specifications for tailored modifications.

More Stories

piece dyed fabrics

yarn dyed khadi cotton

handwoven linen

madhubani wall art

patachittra wall art

eri peace silk